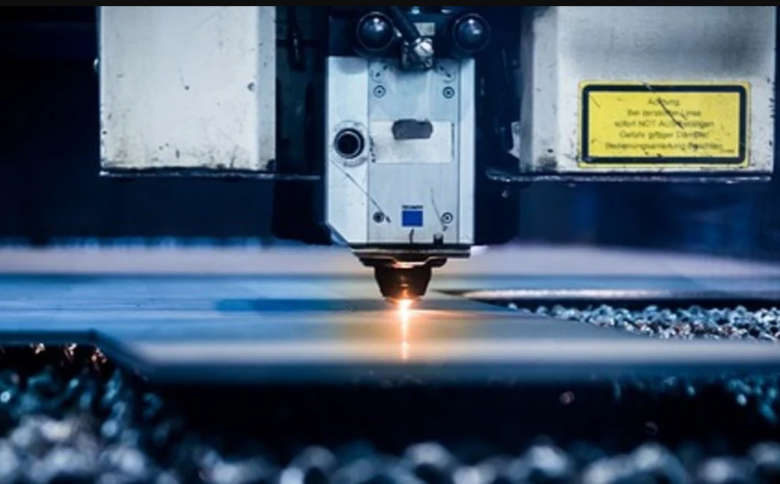

Are you thinking about entering the laser cutting industry? If this is the case, you probably already have an idea of how everything would work, what products you would manufacture, and so on. However, to understand whether your business idea is bulletproof, you must learn everything about this technology.

Naturally, you need to start with the laser cutter. This machine includes numerous features, but the most common question people have is about the materials that can be used. In this article, we will answer this question and also provide you with some additional tips.

Materials you should never cut

First things first, let us provide you with a list of materials you should never cut. There are several reasons for this. Some of them are too thick, others you probably get damaged, meaning that you would destroy the entire pieces, and some are dangerous.

1. Plastic

For example, you need to be very careful with plastic. There is a lot of debate regarding this material, and yes, there are some types you can cut. Nevertheless, at the same time, some of them contain chemicals that evaporate during this process. These chemicals should never be inhaled since they can endanger your health. For example, you should never cut PVC and similar materials that include Bromine, Chlorine, Fluorine, and Iodine.

2. Rubber

Furthermore, there is rubber. Now, there are some types of rubber that cut easily and that are safe to use. On the other hand, there are also those that contain Chlorine, such as Neoprene, so you have to be careful about it. Finally, some types of rubber are not suitable for this application since they will melt when they come into contact with the laser.

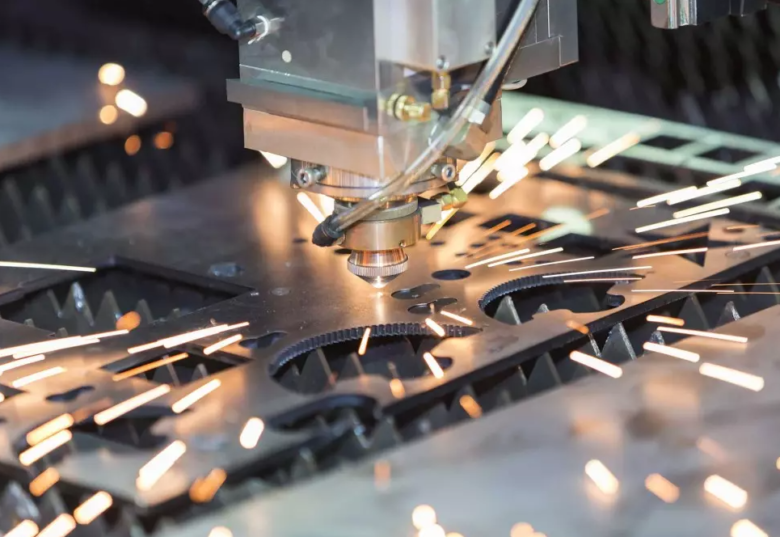

3. Minerals and metals

Lastly, there is a matter of minerals and metals. As you know, many types of metal can be cut with a laser machine, but there are still some that can only be engraved. You have to be very careful when working with Lead, Nickel, Cobalt, Copper, Chromium, and Manganese. When it comes to these, you need to do a test trial first. The most important thing is to choose the right machine if you want to use these materials. It is something you have to think about carefully when selecting the cutter. Naturally, there are several other things you have to consider, and if you are looking for a cheap laser cutter, you should click here to find some recommendations.

Moreover, if you are wondering about stone and glass mirrors, the answer is no, you cannot cut these. However, you can engrave them pretty easily. However, to complete this task successfully, you should use a CO2 laser, so once again, think about this requirement before investing in the machine.

4. Paper and cardboard

Many people are confused about these two materials. Since we have already discussed that some materials can emit toxic gases and burn, it is understandable why these two are confusing. When it comes to these, the trick is to operate the machine smartly. You have to ensure that the beam is not too intense because otherwise, a fire may occur. There is a whole section regarding these instructions, so make sure to go over these before using the cutter for the first time. For example, depending on the thickness of the cardboard, you will probably have to adjust the machine to a slower setting to avoid damage.

Additional safety tips

Since this entire article is about the materials you should never cut due to safety reasons, here are some additional guidelines you need to follow.

-

Never leave the machine unattended

This is, without a doubt, the most common mistake people make. You should never, but never, leave the laser cutter unattended while it is firing beams. Why? Well, it can be a fire hazard, and you need to be present to be able to act immediately in case of a disaster. It is also why you need to test every material beforehand. We have already explained the risks, so we will not elaborate on this any further.

Yes, we know that this process can be quite lengthy, especially for big projects that can take hours. Although this machine includes several safety features, you should never leave it for several hours at a time.

-

Make sure your workshop is pristine

Many people don’t understand that particles left from previous projects can cause a fire. These particles can ignite if they are exposed to the heat the cutter produces for a longer period of time. No, it is not just dust or debris. Yes, these can be found in every workshop, but you need to clean everything thoroughly the moment you are done with your work. Plus, there is also a matter of accidents that occur due to the clutter and tools and materials scattered all around the place.

-

Understand how everything works

Inspecting the cutter and learning every detail about it is, without a doubt, a crucial task you have to complete. Nowadays, these machines are fairly easy to operate, which is why they are available on the market. Nevertheless, this doesn’t mean that you should use it the moment you set it. Instead, take some time to read the instructions and learn how every feature works. If you have any additional questions or doubts, you should contact the manufacturer and ask them for help. In most cases, accidents occur because people don’t know how everything works, so they misuse the machine.

-

Inspect the materials

Finally, this leads us to the final tip we have for you. Even though we have provided you with some common information regarding the materials you should never use, you still have to conduct extensive research on this matter. It is a good idea to do it beforehand to purchase a suitable cutter for your business. Also, make sure to complete this task if you want to include products in your company’s offer. It is the only way to ensure everything will go smoothly, and more importantly, that you won’t throw money down the drain when investing in new merchandise and materials.