There are thousands of new apparel brands starting every year! Many have their sights set on becoming the next LuLu Lemon or Vuori. While it’s important to distinguish yourself from the pack, consider scalability, time to market and the necessity to reinvent the wheel when deciding whether to cut and sew or simply relabel a great existing product.

The most important thing a startup can do is use leverage to conserve cash. How does this translate to relabeling you ask? In this article I will explain how relabeling is a cost savings over manufacturing and how using relabeling to get your startup apparel line off the runway is the smart move over custom cut and sew manufacturing.

Many startup brands incur the cost of developing their own t-shirts! This means sourcing fabric, sourcing suppliers, waiting on long manufacturing times, incurring high shipping and freight costs, storing product, tying up money in inventory to name just a few of the negatives!

A simple solution most new brands overlook is relabeling. Using the relabel process a brand that specializes in shoes for instance can add a t-shirt to its product line up while leveraging manufacturing sourcing and many other costs.

The process for many brands becomes a hunt for the perfect designer who can create templates and create a fit and feel that is unique. The thought process then moves onto how to set your shirt apart from the thousands of other shirts created. Maybe a custom stitch?

Maybe a different neckline? Maybe a drop tail? Maybe unique fabric? The problem is or should I say the solution is that many major blank apparel manufacturers have already solved this problem. If you can dream it, they have done it. Many neckline choices, many colors perfected fits exct. The good news is many of these manufacturers have created these products just for brands like yours! Their goal is for you to rip their labeling out and relabel the shirts they built as your own!

Relabel to Unique

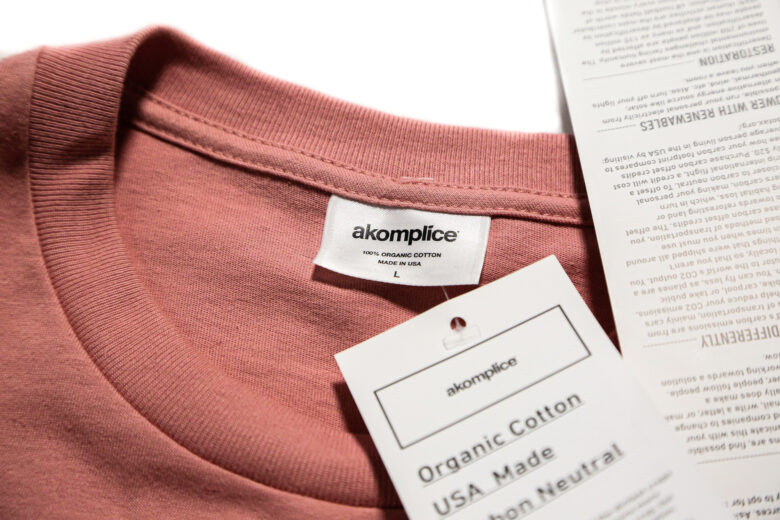

That’s right I said it “Relabel” Apparel unlike many other industries encourages relabeling. What this means is that when you come across many shirts or hats from popular retailers such as Hurley, Quicksilver, LRG and many more you are actually purchasing a Tultex 202 t shirt from BlankStyle or a Richardson 112 hat.

Both Tultex and Richardson encourage the use of their blank product in retail brands, and they have already solved many of the manufacturing headaches you will need to solve such as, Availability, Cost, Consistency, Fabric quality the list goes on and on.

Reservations still exist.. Our brand is special, it’s going to be big, we need this to feel unique. We can’t simply use a mass-manufactured blank and slap our label on it, can we? Well.. yes you can and you can do it without sacrificing “unique” How you ask?

Imagine you could go to an auto builder say Audi and you could buy the car without emblems at a price that is less than half of your retail or their retail, you could add your own emblems and you could even add your own special touches like pinstriping. Why would you ever need to engineer basics like a braking system or an engine? The same goes for Apparel relabeling. You can create a unique product based on a mass manufactured blank that already fits and feels great, and here’s how.

To get started find a fabric and a fit you like through a sampling process. Remember you don’t need your print on it or your tag in it at this stage! Your goal is simply to find the right fit and fabric. Yes, you will incur some cost testing out different blanks, but this cost will pale in comparison to sampling your own cut and sew!

Once you have identified your blank you can purchase it and generally purchase the relabeling at the same time through a company who offers thousands of blank shirts from hundreds of manufacturers and also offers relabeling services.

You can add special touches like a neckline print or even a custom-colored stitch to make your shirt stand out and differentiate it from the blank you originally purchased! When you are finished you will have saved hundreds of thousands, and even the most accomplished eye will struggle to identify the original product.

Your savings include but are not limited to all the time you would have otherwise spent going back and forth with overseas suppliers getting samples that are costly and wrong! You also save all the money it would have cost you to wait, receive your initial shipment and realize you have tolerance issues or defects..

Additionally, assuming nothing goes wrong, and you accomplish the goal of completing your perfect garment you save all of the freight and all of the money tied up in inventory and all of the time in manufacturing along with all of the time freighting the product from the country of origin. Other costs and risks you no longer must worry about include everything to do with customs and international trade!

When you consider a few financial facts, the decision becomes easy. When you don’t have to re-invent the wheel by creating a garment you come out ahead. You use the leverage of the wholesale apparel industry who has already solved your problems for you, and you add your secret sauce. The most amazing part of this solution is that its encouraged and totally legal!

Can you imagine if Nike allowed you to relabel their shoes with your logo on them? You are an overnight footwear genius! Unfortunately, footwear does not work this way for most! Apparel however does. So take advantage of the existing infrastructure and use leverage to create your line.

Relabeling provides a lot of leverage to a startup brand so even if you decide to cut and sew a flagship product, relabeling is a great way to add to your line card with limited overhead. The solution is simple, add your print, and your tag and remove the manufacturer tag. This is legal and encouraged. Happy relabeling!