Painting an industrial building is quite different from painting a commercial or residential building. Industrial paint should offer more functionality protecting the building from corrosion and other hazardous chemicals. High-quality industrial paint provides high-performance perks such as efficiency, durability, and sustainability.

Failing to choose the correct coating may result in maintenance issues and other defects on your walls. Common causes of industrial painting and coating failure emanate from the wrong choice of paint, inadequate surface prep, incompetent formulation, improper application technique, and a non-friendly environment.

Defects in industrial paints and coats can lead to unsightly walls, and it is also a waste of resources. Therefore, buying industrial paint and coating from a reputable supplier is as vital as the project itself like https://www.promain.co.uk/.

Here are some possible defects in industrial painting and how to avoid them.

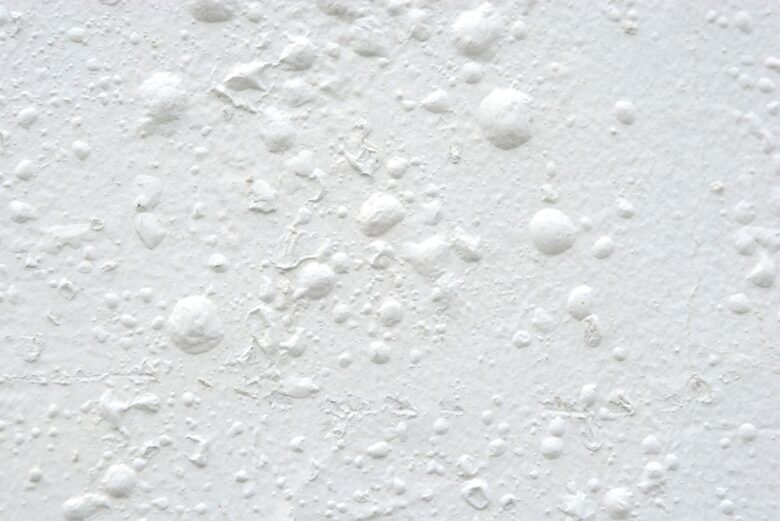

1. Blistering

Blistering of industrial paint appears in the form of broken or unbroken bubbles, and the wall may feel like sandpaper upon touch. The primary causes of blistering paint are surface contamination before paint application and coating applied when the humidity is too high.

Solvent entrapment when the industrial paint is coated too soon or applied too thick is another cause of the blistering. The painter should adequately clean the surface contamination beforehand and use blowers in rooms with high humidity to increase solvent release. Adequate surface prep and application are essential.

2. Cracking

Cracking is very unsightly, and it appears in the form of deep cracks in the coating, exposing the substrate. Causes of cracking include excessive thickness, coating shrinkage, and limited flexibility. Remember that the greater the film, the more likely it is to crack. The remedy is to mechanically remove the coat and apply a new one. You can also sand or blast it.

3. Checking

This defect occurs as narrow short breaks that expose the undercoat. Applying the industrial coat under too high temperatures, excessively thick coats and limited flexibility are some of the causes of checking. The solution is to sand or mechanically scrape off the checked coat and apply a new one.

4. Delamination

Another common defect in industrial paint application is delamination, which refers to the peeling of the substrate or undercoat. The cause of delamination defect in industrial painting is linked to the separation or lifting of paint from a poorly bonded undercoat, smooth or chalky substrate.

In most cases, delamination occurs due to poor surface preparation during the paint industrial application. With this defect, you have to sand or mechanically remove all the loose paint, clean or roughen the smooth substrate and recoat afresh. Cleaning and preparation are vital to ensuring that delamination doesn’t occur again. You should also prevent surface contamination before coat application.

5. Peeling

This defect occurs when the coat peels from the substrate. The common cause is stress from the cured or contracted coat which doesn’t adhere well to the substrate. If the peel is extensive, you should mechanically remove the coating from the substrate before applying a new one.

If the peeling is limited, you can spot remove the loose coats and apply a flexible one. Note that choosing the right coat and using it correctly is necessary to prevent paint peeling.

6. Orange peel

Orange peel refers to finely dimpled surface texture or uneven textured surface, which looks like dull orange skin. Some reasons for such defective industrial paint include poor atomization of a low-pressure spray or the painter positioning the spray gun too close to the surface.

First, the solution is to use the correct applicator and engage an experienced industrial painter. A professional contractor knows how to position the spray gun to ensure the coat adheres well. Before the coating cure, brushing out the excess fluff and adjusting the spray conditions are essential.

7. Fish eyes

Fish eyes occur in the form of small holes in the coating film. Applying the coat over oil, dirt, or silicone causes the wet film to pull apart, exposing the underlying substrate or finish. The solution is to scour back until the contaminated surface is degreased, then allow it to dry before applying a topcoat.

8. Cratering or pitting

Craters are small identical indentations in the film caused by trapped air pockets in the film during coat spraying. The remedy is to blast or sand the coat to a smooth finish, then apply a fresh one. Also, consider improving the spray technique to prevent cratering from occurring again.

9. Blushing

You can quickly tell blushing on an industrial building as it is unique. It manifests as a flat finish with a milky appearance, which means the coating may have been exposed to moisture in the curing process. An unbalanced thinner in spray application or moisture condensation in high humidity is the cause of blushing.

You have to abrade back until the blush is over and apply a fresh coat to rectify such a defect. You should also consider the relative humidity and temperature when respraying to prevent the coat from blushing again. Ensure suitable environmental conditions when applying the coat.

10. Mud cracking

Another common defect in industrial paints and coats is known as mud cracking. These are deep, irregular cracks that resemble dried mud caused by an inflexible industrial coat applied too thick. The remedy is to mechanically remove the coat and prep the surface before applying a thinner coat. Ensure you stick to the recommended thickness when applying the industrial coat.

11. Overspray

This defect is also known as pebbly, flat or dry surface, or dry spray. It happens when the particles reaching the surface are not wet enough to level because the solvent is evaporating too rapidly. It also results when the coating particles fall outside the spray pattern, or the gun is too far from the wall surface.

The remedy is to remove the dry brush followed by solvent wiping before curing. Then after curing, sand the surface and apply another coat.

Conclusion

The wrong industrial paint and coat choice can result in the defects discussed above. Moreover, it is best to choose a skilled and experienced painter for industrial painting.