A chainsaw is a powerful tool that can save you a tremendous amount of time and effort in a variety of tasks, from tree felling to pruning. Depending on the configuration, it can be used in domestic as well as commercial settings.

However, it’s not the saw alone that determines your level of success with it. According to toolsngoods.com, inadequate chain quality can cause numerous problems, in particular compromising the quality and precision of the cut and getting blunt sooner than it should. Using a suboptimal chain also means you’ll need to invest more effort in whatever you are doing.

With this said, the question arises, how to choose the perfect saw chain for your purpose? It turns out the accessory comes in all shapes and sizes, so you need to understand which specific type will work best for you. Let’s explore the key parameters that determine chain use in chainsaws.

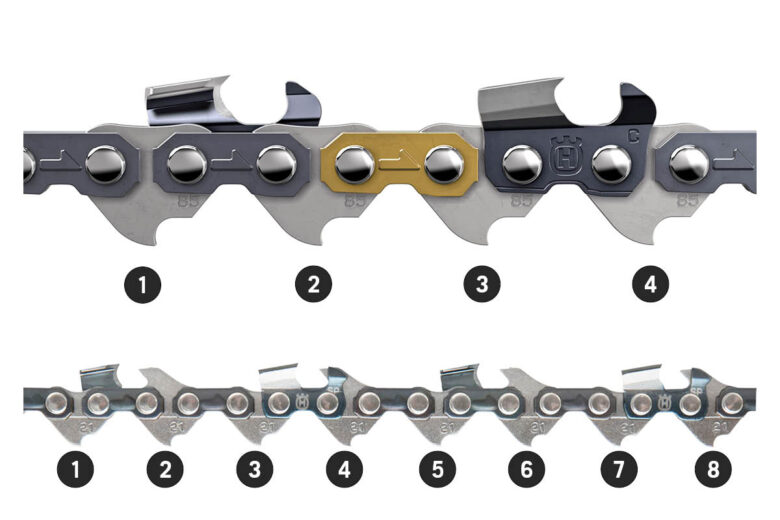

Cutter Shape

The way cutting teeth are shaped in a saw can influence the speed of cutting as well as the risk of kickback and how quickly it will dull. There’s a wide range of cutter shapes on the market nowadays, but full-chisel, semi-chisel, micro-chisel, and low-profile are the most common.

Due to their square corners, full-chisel teeth deliver maximum aggressiveness and cutting speed. This also means they tend to go blunt really sooner than other cutter types and are relatively difficult to sharpen. Full-chisel chains are recommended for dirty sawing in challenging settings. While popular with professionals, this chain type can be difficult to handle for inexperienced users due to higher-than-average kickback risk.

Rounded semi-chisel cutters last longer and rarely cause kickback. These are common in professional and home settings alike. However, cutting speed is relatively low with rounded teeth, although you spend less time sharpening them in tough conditions.

Micro-chisel chains are even more rounded. They sharpen really easily and can withstand difficult conditions while providing a smooth cut and are thus very popular with home users.

Finally, casual users who put safety first tend to choose forgiving low-profile chains. While rather slow, they are also the easiest to sharpen.

Chain Arrangement

Chain arrangement, also referred to as chain sequence, refers to the spacing between cutters in the chain. Confusingly, there’s another term that denotes a similar idea, namely pitch (see below). However, pitch is about the inter-link distance, while chain arrangement deals with that between teeth, or cutters, since not all links contain cutters.

Full-complement chains are known as standard or full-house type. They consist of alternating left and right cutters with drive links between them. If you purchase a non-professional saw, chances are high it will come with a full-house chain. This configuration can be used on saws with a guide bar of no more than 24 inches. Its key advantage is that it delivers the smoothest cut, which is especially important in applications where you need a clean finish. It’s also a one-size-fits-all solution, although it tends to be slower than others.

Semi-skip chains are more efficient compared to standard chains. They have an alternating structure with one drive link between a pair of cutters, then two drive links between a pair of cutters, then one, and so on. This means a good balance between cutting speed and smoothness. Semi-skip chains can be used with longer bars and are generally considered to be a specialist option, ideal for situations that require increased cutting capacity.

If cutting speed is your top priority, you should consider getting a full-skip chain. This cutter arrangement is also known simply as skip type. Instead of one drive link, there are two connecting each pair of cutters. That is, skip chains have fewer cutters as compared to the standard configuration. However, impressive cutting capacity is not uncommon, usually achieved through a long bar. This option is the fastest but also the least smooth, making it popular with firewood cutters.

Pitch and Gauge

You want the chain that you purchase to fit your bar. That is, you need to know the pitch and gauge that you are looking for.

Pitch describes how widely spaced the drive links are in the chain. You can measure it by measuring the distance between three consecutive drive links, which you then need to divide by two. There are two common ways of denoting pitch, as fractions of an inch, such as 3/8″, or as decimals like .404”. Chains that have a larger pitch tend to be bulkier. Essentially, it’s all about finding the right balance between strength, cutting power, and weight. 3/8″ (0.325”) is generally considered to be a good, flexible option, and is very common. Check your chainsaw bar to see the required pitch.

Gauge is essentially the thickness of the drive link, which translates to how wide a groove in the bar it will fit into. It’s therefore the portion of the drive link that needs to fit the groove that you need to measure. On the bar, it’s usually printed alongside the pitch. The rule of thumb here is to choose the lightest option that will withstand the operating conditions.

Specialist Chain Types

Square ground chainsaws have a full-chisel design optimized for tough operation to deliver extreme cutting speed without getting dull too soon. Their main limitation is that they are difficult to sharpen and might require special equipment.

Ripping chainsaws are distinguished by extremely shallow 10-degree round cutters. Designed specifically for power mills, they are the perfect tool to cut wood parallel to the wood grain when making planks and boards, which helps minimize chips and produce extremely smooth wood surfaces.

Summing It Up

Today’s chainsaw market has a lot to offer in terms of chains, from professional-grade, specialist options to versatile accessories. If you are a home user, choose one that fits your bar gauge and pitch and look for the balance between speed, cut smoothness, and maintenance frequency, which depends primarily on cutter shape and chain arrangement.