Collaborative robots have performed beyond many people’s expectations in the last couple of years. In a few decades, they will be in demand in many more industries. In the last few years, the number of industries using collaborative robots has increased significantly.

The future of robotics looks bright as their use is set to rise in the coming years. If the pandemic has taught the industrial world anything, it is that robots are needed now more than ever. Human to human interaction has been drastically reduced but business cannot take a break, wouldn’t you agree?

However, with or without human workers, industrial robots, as well as cobots, are crucial in most industrial operations. Below are some of the industries that incorporate cobots in their industrial operations. For additional information, visit Universal-Robots.

What Are Cobots?

Traditional industrial robots are programmed to do one task at a time and from a distance. These robots are large, heavy, as well as strong, but only meant to do simpler tasks.

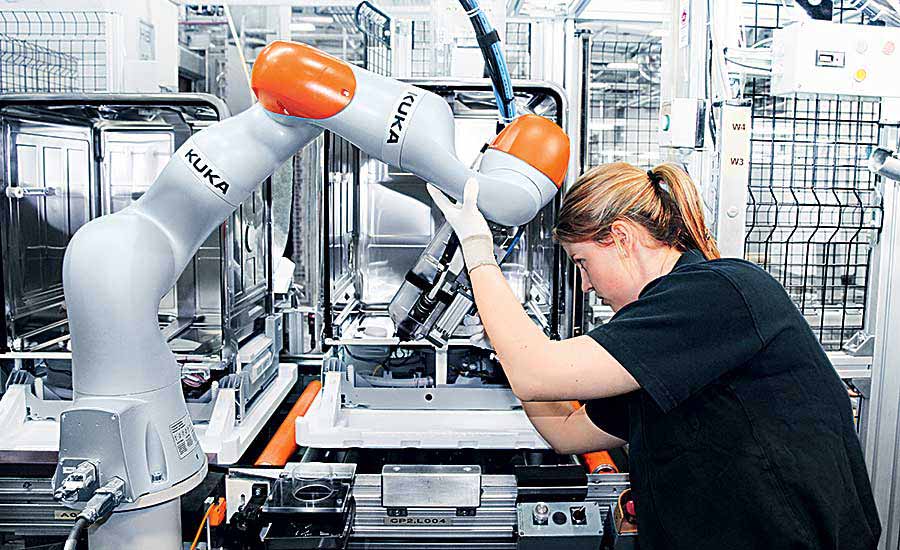

In contrast, a cobot offers direct physical interaction between a person and a general-purpose manipulator that is controlled with the computer.

Most of these cobots can be customized and integrated into the production system. These are a lot more mobile, fast, and are often small and lightweight robots that are super easy to navigate and move from one place to another.

Where Collaborative Robots Will Be Needed: Top 6 Industries

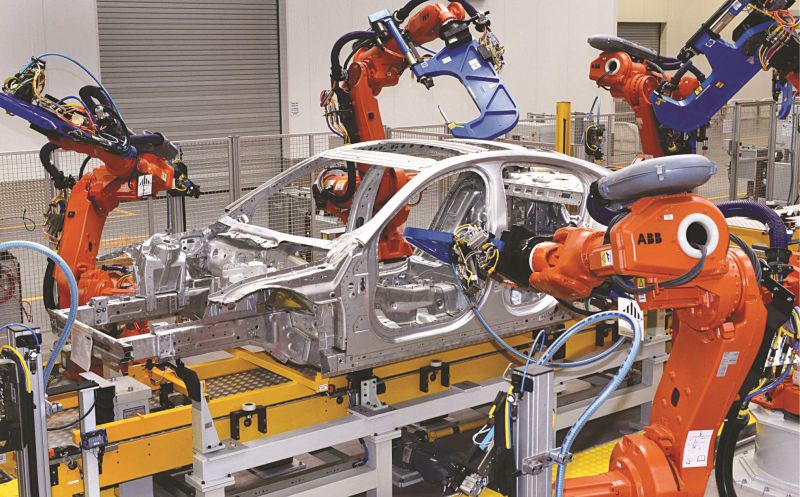

Automotive

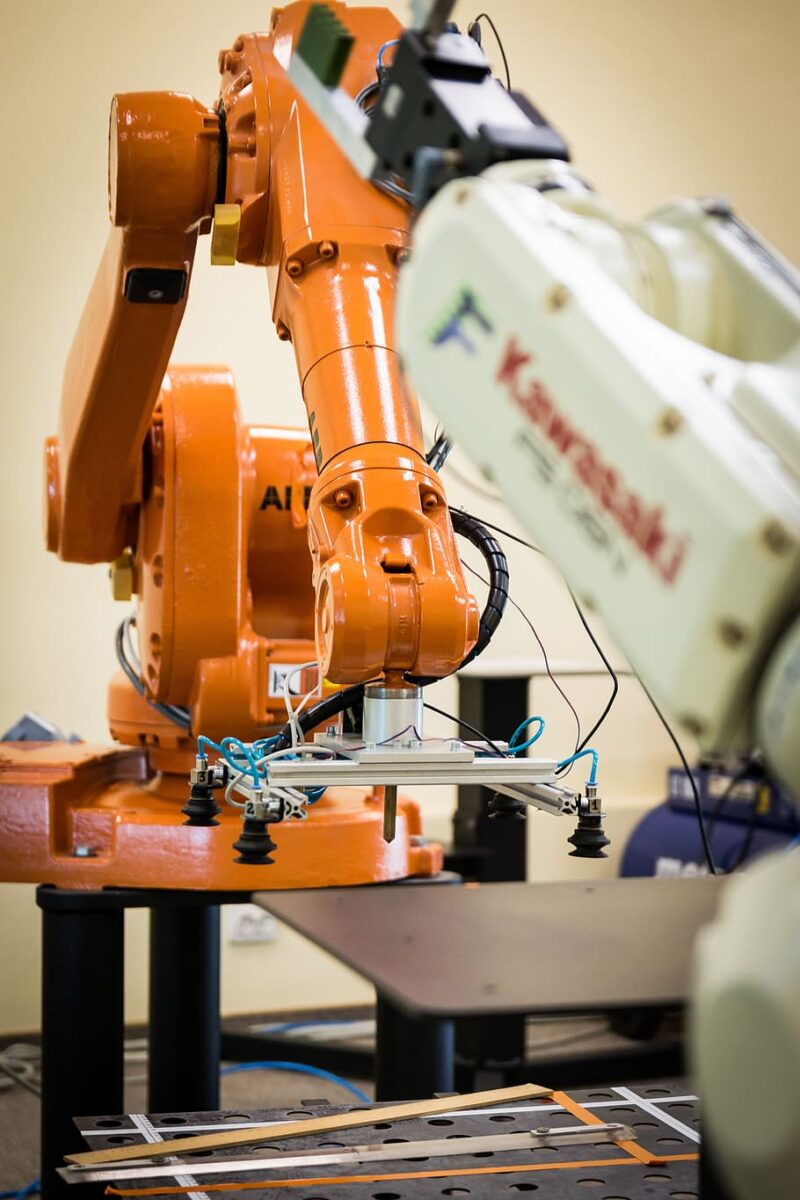

It does not look like the automotive industry will be doing without cobots any time soon. Industrial robots have been synonymous with automotive manufacturing for the longest time. However, the industry has adopted cobots for delicate manufacturing tasks.

These include the following tasks that demand precision, welding, and painting.

Manufacturers are increasingly relying on collaborative robots to perform delicate jobs that are delicate and require controlled force. They are programmed to detect when more force is required and will adjust to just the right amount.

Electronics

Electronics involves a decent amount of high mix, low volume production. Hence, micro-manufacturing is part of the package. Such tasks are best performed with precision which can only be achieved by robots,

Other tasks performed in the industry by collaborative robots include:

- Inspection

- Dispensing

- Assembly

Being easy to program, cobots are the perfect fit for electronics. You can switch from one program to another by simply pushing a button and not worrying if they will get it done. Also, vision sensors to detect parts not easily perceived by the naked eye.

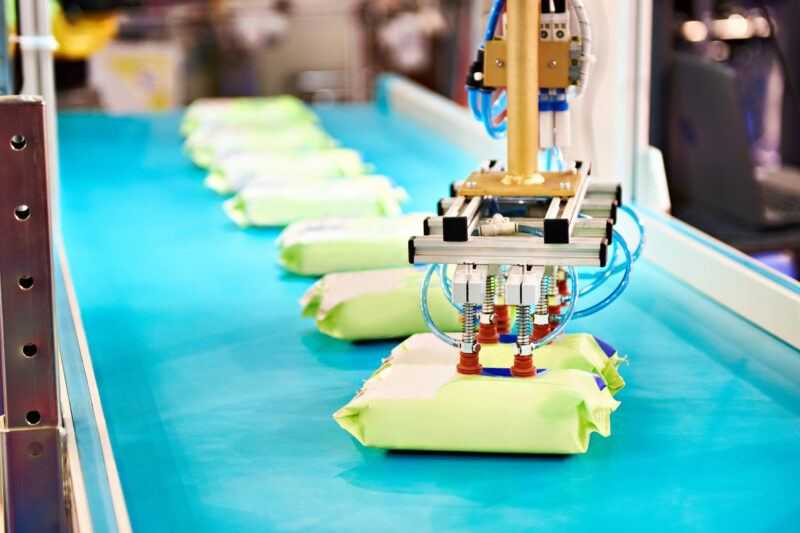

Packaging

The packaging industry has benefited greatly from robotics. While packaging is a simple enough task, it is done repeatedly over a longer period of time. Humans would find it mind-numbingly boring especially if that is all they do all day.

The food industry packages delicate products such as soft foods for transportation. Collaborative robots are best suited to perform these tasks as they are fitted with the appropriate end effector for delicate handling.

Warehousing

Warehousing includes tasks such as picking and packing as well as palletizing. These tasks are best suited for robots for reasons that have been discussed previously. Humans can be relieved from duties that require no cognitive skills such as picking and placing.

They can then move on to skills that are more challenging and fulfilling. Also, warehousing tasks such as the aforementioned involve quite a bit of bending, lifting, and twisting which can be hazardous for the human body. This is why robots are a safe (and smart) bet in this case.

Manufacturing

Manufacturing applications today cannot be performed competitively without robots. Competition in business demands that enterprises put their best foot forward at all times. Therefore, product quality, turnover, and volume are aspects that you must take into consideration. Collaborative robots are being incorporated in many manufacturing plants. They are easy to program, cost-effective and perfect for even small businesses.

Agriculture

The agricultural industry may not have been as fast to jump onto the cobot wagon. However, in recent years, there has been a rising demand for robots in the industry.

Tasks such as weeding, harvesting, and application of fertilizer can be tedious, repetitive, and, ultimately, boring. Some women also hate doing similar tasks on a daily since they are so time-consuming and damaging to their skin and nails. Robots are being used to perform these tasks especially over large tracts of land.

Moreover, finding workers to perform these and other farming tasks has become increasingly difficult. Robots provide the perfect solution.

Top 4 Reasons Why You Should Have Cobots

1. They are smart & safe

This class of robots will work seamlessly and alongside humans. This robot is a collaborative kind that would never hurt a person, and being and working alongside them is safer than ever.

2. Great cooperation

Cobots can behave smartly and they are left in the open for anyone to work with. You can use them for different and complex tasks that cannot fully be automated. If you need great cooperation for repetitive or droning tasks, you will love them!

3. They are teachable

These cobots are flexible and do not require any expert knowledge when it comes to pretty much anything. All you need is a computer or a tabler to put them in play. Some robots are also programmed by moving the arm in the required pattern, which makes their use and maintenance super easy.

4. You can use them anywhere

These robots have better sensors that are advanced, which makes them easy to use anywhere. They will easily detect objects or people on their way and will stop if it is necessary. You can move them around with ease from one point to the other.

Conclusion

Collaborative robots have made it possible for even small manufacturing plants to automate their processes. The demand for them can only grow as they have taken businesses to new levels of production. In 2024, everyone has thought about getting one in order to speed up their business!

What is more interesting is that cobots have allowed businesses to automate tasks that were impossible to automate. Also, they have helped to bridge the labor gap as they take up mundane tasks that humans are reluctant to perform. Doesn’t this sound like a dream come true, and how hesitant are you to get yourself one cobot?!