Figuring out the type of material to use for the structure of a building seems like one of the most fundamental questions and looks like it should be fairly easy. However, it’s not as easy as it looks, and it became far more complicated with the massive growth of the steel fabrication industry as a whole.

There are three main variations of building structures that could be used when it comes to materials. The wooden one is the oldest one by far, and the one used the least these days, for a number of reasons. This leaves concrete as the only material that is competitive enough in comparison when it comes to building frames.

In comparison, steel has a number of advantages as the main material for a frame of a building. Some of these advantages are:

- Easy to predict stress levels and weight limits;

- Impressive strength;

- The relatively light weight of steel as a material;

- Easy strengthening process;

- Advantages of mass production and prefabrication;

- Ductility;

- Impressive construction speed, etc.

It would also be fair to say that steel has its own share of disadvantages and shortcomings. For example, steel is a material that is susceptible to intense heat, meaning that fireproofing a building structure is pretty much a necessity. Another potential problem here is the cost of steel structures – while not really overpriced, steel structures still cost more than their competitors, making it harder to market this material as a whole.

Another notable problem of steel is its corrosion weakness – even though the only structure types that would suffer greatly from this factor are bridges and other structures that are exposed to both air and water on a regular basis.

Since a steel frame as a whole is called steel structure and is a combination of multiple different types of steel parts, it’s only fair to list at least some of them. There are sheets, plates, rail profiles, angles, rods, I-beams, and, of course, trusses.

The steel truss is a steel structure type, one of the main four steel structure types out there. The other three are steel grid, portal frame, and steel building frame.

A steel grid is a spatial structure type that is a combination of multiple rods in a specific way or form. Grids are generally not too flexible and have a great resistance to many weather factors, which is why it’s a perfect structure type for gymnasiums, hangars, exhibition halls, etc.

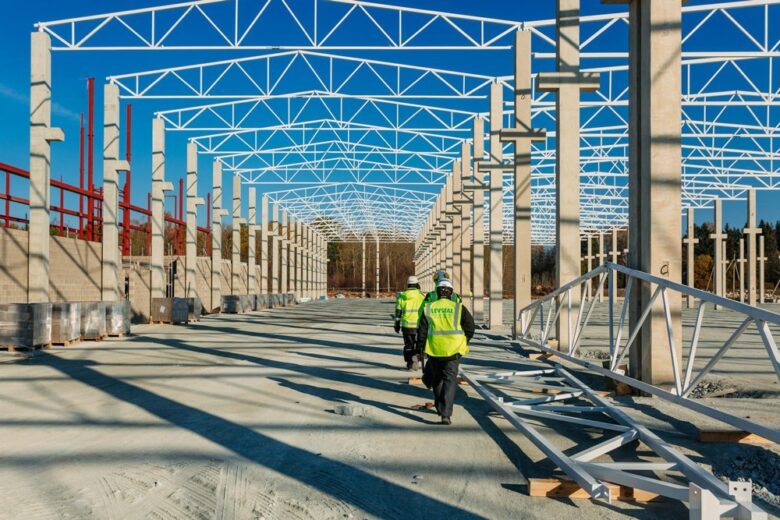

A portal frame, on the other hand, is a structure type that is a combination of steel pipes, section steel, and C/Z steel. It is the most popular structure type out of the four, and it is widely used for a variety of different buildings, be it for commercial, industrial, institutional or agricultural purposes. The most popular example of a portal frame is a standard hangar/warehouse building that you can see pretty much anywhere in the world.

A steel building frame is pretty much exclusive for multi-story buildings – since it is a combination of columns and beams that must handle both horizontal and vertical pressure in spades. High-rise buildings, conference buildings, and commercial offices are the most popular examples for this one.

The last, but not the least, is a steel truss – a myriad of rods that are connected to each other, creating a surprisingly durable and lightweight structure capable of withstanding massive amounts of weight with reduced steel usage. Some of the more popular examples of these are TV towers, oil platforms, roofs, bridges, etc.

For example, let’s imagine a roof truss and talk about it a bit more. A regular roof truss usually consists of a large variety of components, both small and big. Some of the more basic and common components of a regular roof truss are presented in a list below:

- Joint – a part where two or more components of a truss intersect;

- Node – the part where several different parts of truss panels intersect with each other;

- Chord – an element that bears most of the weight of a structure, they also form an outside structure (outline) of the roof truss;

- Apex – as the name suggests, the apex is the highest point of a roof truss, a single point where rafters meet;

- Cantilever – another important part of a structure that also extends towards the support and beyond;

- Nominal Span – a length between further support parts (their outside edges), is also the tie beam length;

- Clear Span – the same idea as with the nominal span, but inside edges are taken into consideration when calculating the length;

- Bearing – one of the structural elements that is used to support the weight of a truss (also works for walls, not just roofs);

- Bottom Chords – the lowest part of a roof truss, usually a large part of a bottom of a truss;

- Nail Plate – a galvanized plate that is used to further support the connection between different parts of a truss;

- Cantilever Strut – an addition to a cantilever that is connected to a bottom chord above the cantilever itself;

- Heel – a point where the top and bottom parts of a truss intersect;

Levstal can offer its prolonged experience in steel fabrication to create steel trusses for buildings of both commercial and residential purposes. There are many benefits that these steel trusses are capable of offering, including:

- Easy installation for steel trusses and other parts of steel structures;

- The inability of combustion – due to the nature of steel as a fireproof material;

- Little to no potential in terms of deformation;

- Uniformity – the ability to steel trusses to be suitable for even the most unusual shapes and forms of steel structures;

- Highly durable material as a whole – no damage from moisture and/or insects;

- A relatively small weight of the structure, in terms of a strength-to-weight ratio of steel structures;

- Prolonged usage – most of the properties are retained after decades of use.

Levstal’s steel trusses are the pinnacle of performance and durability, suitable for most use cases with steel structures. Our steel trusses are made with high precision and retain original properties for long time.