The world market has very clear requirements when it comes to product quality. Of course, when you want a good product there is no deviation from a certain standard. In line with that, today there is a great demand (it is predicted that it will be even higher) for naturally preserved products such as food, medicines, etc.

What does it mean? This means that more attention is paid to the finishing, and physical and chemical treatment is reduced to a minimum. This trend requires all manufacturers to pay strict attention when packaging. Those who do that get top quality products, which are very safe for our health.

In order for a product to still contain its nutritional characteristics, its packaging must meet certain conditions. The most important thing is that such packaging does not allow the passage of microorganisms and other things that disturb its condition.

Therefore, the choice of packaging or its material and method is crucial. Of course, we leave it to the experts to assess the quality of that. Today, there are many companies that deal with the assessment of quality. That means we are talking about the integrity of the packaging. You can read more about it below.

What actually is it?

As you may have concluded, the integrity of packaging represents the potential of it as protection of the product from external influences such as certain physical or chemical threats, including microorganisms. For the safety and health of consumers, there is a process by which successful packaging integrity is achieved.

This includes the following :

1. Following the requirements

These are integrity regulations. This means that before making any decision or plan, you need to look at the characteristics of the product or what conditions it needs. We mean all the conditions that will not spoil the quality of the product, which are in accordance with its shelf life and other functional requirements. It is important that each of the requirements meets the end goal criterion.

These criteria refer to the sterility of the product, its protection (as we said – from external influences), verification of shelf life, control of distribution, and temperature. All this is extremely important for the integrity of the product and the packaging itself, ie its stability due to proper insulation.

2. Assessment of it

During this process, the possibilities of the product are checked. More precisely, this refers to satisfying the ultimate goal, which is not possible without a prior assessment of the product itself, on the basis of which we move on to the next step, such as design, etc.

Before introducing a new product into the process, it is necessary to first consider what machines, materials, and, above all, the possibilities you have at your disposal so that the entire process can be completed. It is necessary to check some questions such as: Is there all they need for equipment, what are the costs of the new one, what are the costs with the current one and so on.

Therefore, this step requires the compilation of a list relating to the elements intended for inspection and processing of packaging.

3. Distribution factors

Package storage may encounter certain inconveniences. Of course, it is necessary to anticipate this in advance and to take all preventive measures that are necessary in this case. The challenges of the environment are different, and we have listed some of them in the text. Sometimes you cannot rely on the current temperature and other weather conditions. Then, it is necessary to take into account the load of the vehicle as well as the space in which the product and packaging are stored.

This means that in addition to the primary packaging, there should also be a secondary one, and that is exactly the type of prevention that provides protection. In order not to predict the condition and to arrive intact, it is best to take into account all of the above, research the conditions and consult with the company in charge of that assessment.

They will devise a strategy for you to raise efficiency to a higher level. These are logistics partners or a logistics company that helps the product reach its destination safely.

4. Risk assessment

No matter how many preventive measures you take, the risk sometimes comes in any case. There are simply things that we cannot influence, but they also rarely happen to everyone. However, another type of prevention is exactly the plan B that you must have if this situation occurs. This means that you must assess the worst possible outcome or level of risk in advance.

This is a systematic process that should identify all the negative impacts that can harm the product and all its parts of it. There are consultants who help many companies to do this part of the job properly.

5. Prototypes

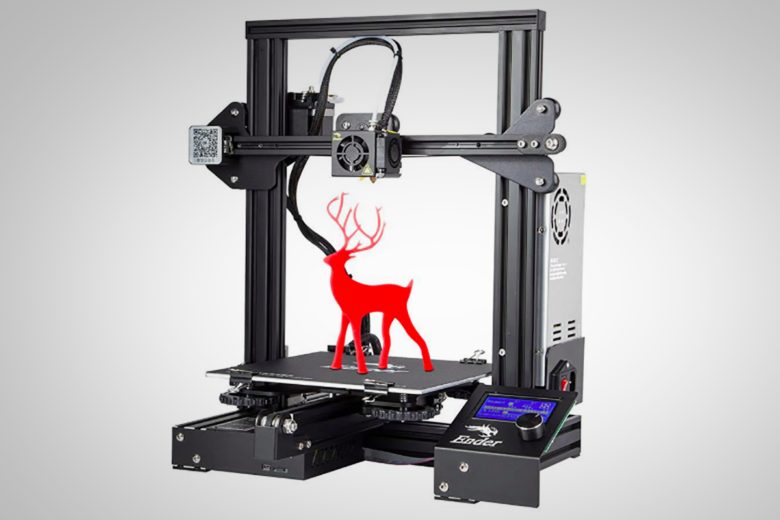

After all these, it’s time for prototypes to assess the integrity – and in order to start producing the right one, you need to do this first. This is tested using a 3D printer and other technology that can successfully perform this function. In this way, one pre-experiments before taking the final step in the design.

This is an economical move since the tools for the original packaging require much more money and other resources, as well as time. Also, this is often used to get feedback from consumers.

6. Performance check

This is the last step that provides the final result when it comes to security. Whether it will meet absolutely all the conditions of success can be checked using this process. This includes previous items such as shelf life, environment, distribution, risk, etc. More precisely, this is a type of final review and the last one that contains precise results. For the final check, it is best to hire professionals like FlexPak, who have all the necessary machines and procedures to check the product before launching it on the market.

Conclusion

The latest statistics claim that great success has been achieved in the packaging industry and that the industrial sector is extremely growing. If you are in this business, know that you are not in the minority and that the competition is growing every day. That is why it is important that you provide only quality when it comes to your services, and you will not be able to achieve that if you do not cooperate with experts who can help you with that.