As an employer, you have the power to create a culture of excellence and prioritize the well-being of your customers. Taking authority of every food processed in your kitchen and ensuring it sits with the best standards and quality. There is nothing to hide about employers’ crucial role in maintaining food safety and quality in commercial kitchens.

To achieve the highest standards and build a strong and loyal customer base, you, as an employer, should ensure that all the necessary safety policies are implemented and followed in your workplace. Whether by implementing the principles of HACCP (Hazard Analysis and Critical Control Points) or by taking other effective techniques. By implementing effective measures and not compromising on the safety and quality of your book, you, as an employer, can take your business towards the road to success.

In this article, we will discuss actionable steps you can take to ensure food safety and quality in your commercial kitchen. Let’s get started!

Understanding HACCP Principles

Source: wonmed.vn

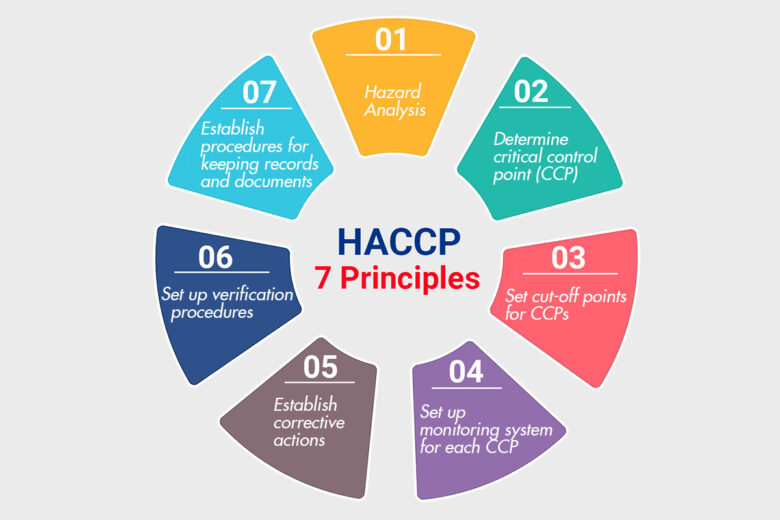

HACCP, an internationally recognized food safety management system, focuses on preventing hazards rather than merely inspecting the final product. It comprises seven core principles that work together to establish a robust food safety framework.

1. Conducting a Hazard Analysis

To begin, commercial kitchens must conduct a comprehensive hazard analysis. This involves identifying potential hazards, such as biological, chemical, or physical contaminants, and assessing the risks associated with each one. By understanding the hazards, kitchen staff can take proactive measures to mitigate them effectively.

2. Identifying Critical Control Points (CCPs)

Critical Control Points (CCPs) are specific steps in the food production process where control can be exerted to prevent, eliminate, or reduce hazards to an acceptable level. In a commercial kitchen, examples of CCPs include cooking temperatures, cooling processes, cross-contamination prevention measures, and cleaning procedures. Identifying these crucial points ensures that hazards are effectively managed.

3. Establishing Critical Limits for Each CCP

At each CCP, critical limits must be established to determine what is safe and acceptable. These limits include time, temperature, pH levels, and moisture content. Commercial kitchens can maintain control over potential hazards and uphold food safety standards by setting these boundaries.

4. Monitoring CCPs

Continuous monitoring is essential to verify that CCPs remain within the established critical limits. Regular checks, such as temperature monitoring, visual inspections, and quality control tests, help ensure that food safety protocols are adhered to and that potential risks are promptly addressed.

5. Implementing Corrective Actions

Even with careful monitoring, deviations from critical limits may occur. That’s where corrective actions come into play. Commercial kitchens should have clear procedures in place to address these deviations promptly. Staff should be trained to recognize and rectify such situations effectively, minimizing the risk of compromised food safety and quality.

6. Verifying the Effectiveness of the HACCP System

Regular verification procedures should be performed to validate the effectiveness of the HACCP system. Internal audits and inspections provide an opportunity to evaluate the HACCP plan’s performance, identify areas for improvement, and ensure ongoing compliance with food safety regulations. Additionally, external verification through third-party audits can further enhance the credibility and trustworthiness of the kitchen’s food safety practices.

7. Establishing Record-Keeping and Documentation Procedures

Source: fosterrefrigerator.com

Accurate and organized record-keeping is crucial for effective HACCP implementation. Keeping records of temperature logs, corrective actions, supplier certifications, and employee training helps track and demonstrate adherence to food safety protocols. These records also serve as valuable references during inspections and audits, providing evidence of a commitment to maintaining food safety standards.

Other Steps to Ensure Food Safety and Quality

Here are some of the measures behind HACCP principles that you can implement in your commercial kitchen and further enhance your food safety and quality:

1. Invest in Comprehensive Training

To ensure a well-run commercial kitchen, it is essential to establish a strong foundation of comprehensive food safety training. Keep your employees’ knowledge up-to-date by providing initial training and regular refresher courses. Consider HumanFocus food safety training, which offers some of the best e-learning courses accredited by reputable organizations worldwide. Additionally, focus on proper handwashing, cross-contamination prevention, safe food storage, and cooking temperature requirements. Interactive training sessions, hands-on demonstrations, and quizzes can make learning engaging and effective.

2. Promote a Food Safety Mindset

Source: fooddocs.com

As an employer, instilling a food safety mindset throughout your team is essential. Emphasize the importance of hygiene, cleanliness, and safe food handling practices. Encourage open communication and collaboration, where employees feel comfortable reporting potential hazards and suggesting improvements. By fostering a culture of food safety, you create an environment where everyone is committed to upholding high standards.

3. Enforce Good Hygiene Practices

Maintaining high standards of personal hygiene among your staff is paramount. Ensure employees follow proper handwashing procedures, use gloves when necessary, and wear clean uniforms or protective clothing. Regularly reinforce hygiene practices through signage, training, and periodic evaluations.

4. Create and Enforce Standard Operating Procedures (SOPs)

Standard Operating Procedures (SOPs) provide clear guidelines for various tasks in your commercial kitchen. Develop SOPs for food preparation, cleaning and sanitizing, equipment maintenance, and other critical processes. Ensure that employees are trained on these procedures and regularly evaluate their adherence. Update SOPs as needed to reflect best practices and new regulations.

5. Establish Effective Supplier Relationships

Source: 7shifts.com

Collaborate closely with your suppliers to ensure the quality and safety of the ingredients and products you receive. Choose reputable suppliers that prioritize food safety and regularly conduct their own audits. Require certificates of analysis and documentation to verify product quality and compliance with regulations. Maintain open communication with suppliers to address any concerns promptly.

6. Monitor and Maintain Equipment

Regular equipment maintenance is essential for both food safety and operational efficiency. Implement a preventive maintenance schedule for all kitchen equipment, including refrigerators, ovens, and food processors. Train employees to identify signs of equipment malfunction or wear and tear. Promptly address any issues and keep detailed records of maintenance activities.

7. Implement Effective Cleaning and Sanitizing Procedures

Maintaining a clean and sanitized environment is crucial in preventing contamination. Develop comprehensive cleaning and sanitizing procedures for different areas of your kitchen, including work surfaces, utensils, and equipment. Train employees on proper cleaning techniques, use appropriate cleaning agents, and establish regular cleaning schedules. Regularly verify the effectiveness of your cleaning procedures through visual inspections and testing.

Conclusion

As an employer, you have a significant role in ensuring food safety and quality in your commercial kitchen. By promoting a food safety mindset, investing in comprehensive training, implementing HACCP principles, enforcing good hygiene practices, establishing SOPs, maintaining strong supplier relationships, monitoring equipment, and implementing effective cleaning and sanitizing procedures, you create a safe and reliable environment for your customers.

Remember, food safety is a continuous commitment. Stay informed about industry best practices, regulatory requirements, and emerging trends. By prioritizing food safety and quality, you not only protect the health of your customers but also enhance your reputation and build customer trust and loyalty.