Do you know that there are around 4.66 billion active Internet users, encompassing 59% of the total population globally? Thanks to fast-paced technology advancements such as the Internet of Things (IoT) and cloud, we are now more connected than ever. Organizations are now more empowered – going paperless, embracing the cloud technology, and taking their business-critical data from traditional spreadsheets to modern database management systems.

Over 2.5 quintillion bytes of data are created every day…and this number is truly overwhelming. The evolution of the Internet of Things (IoT) has further accelerated the pace of data generation and transmission, with over 90% of the data in the world being created over the last two years. Given this bulk amount of data being produced and transmitted each second, there has been a drastic shift towards cloud computing.

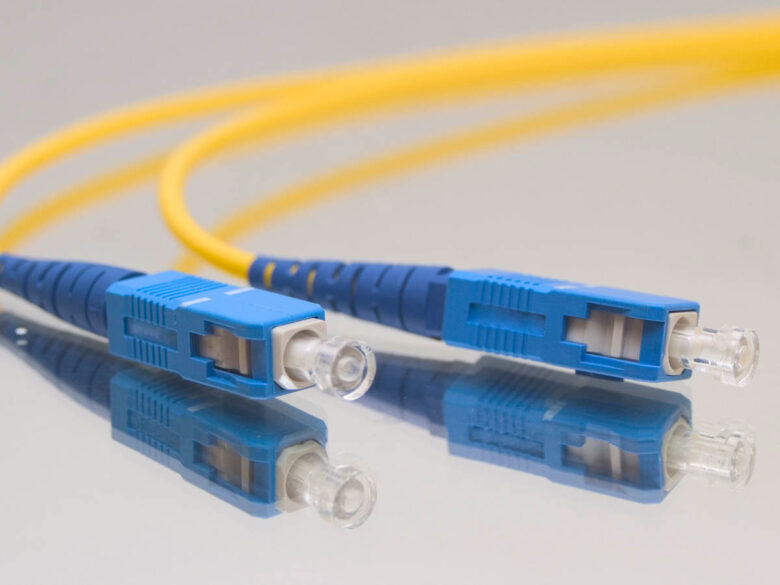

Wondering how data is being transmitted or stored on the cloud? The answer is- fiber optic cabling system. It transmits data at a lightning-fast speed, providing excellent and reliable connectivity between computers, devices, and servers. Even for cloud technology, fiber optic systems function as a powerful foundation, allowing the storing of data at the speed of light.

For ultra-fast and reliable data transmission & cloud storage, accurate and reliable fiber optic measurement is the essence of quality control. High precision measuring tools provide for real-time measurement of optical fiber cables, product categorization, process testing, and optimization. Here, we will discuss how such devices have been facilitating the manufacturing of innovative production lines today and in the future.

How Fiber Optic Cables Transmit Data?

Fiber optic cables are made of hundreds of optical fibers that are thin strands of plastic or glass less than 1/10th of the thickness of human hair. These cables transmit data through high-speed pulses of light. There is another layer, known as cladding, enclosing the central fiber. It causes the pulses of light to bounce off the walls of the cable and prevents leaking out from the edges. This enables the signal to travel at a longer distance without attenuation.

Optical fiber technology converts an electrical signal into light that enables it to transmit data at an incredibly faster speed – most often at a speed close to the light. As compared to satellite connections or copper wire, fiber optic cables have a wider range of frequencies that enable data transmission without quality loss. As such, you can enjoy a remarkably higher bandwidth capacity. Offering ultra-fast speed and higher bandwidth than its alternatives, fiber optic cables allow businesses to upload, download and store data more quickly.

Importance of Fiber Optic Testing & Measurement

Over the years, the fiber optic network has rapidly expanded and evolved, revolutionizing how data is transmitted and stored for critical applications like 5G communication, FTTH, submarine networks, etc. This has emphasized the need for high-precision fiber optic measurement and testing.

Owing to the large-scale demand and use of fiber optic networks globally, it is important for the manufacturers to perform robust testing to stay compliant with regulatory standards and maintain optimal performance, interoperability, and consistency. Testing helps certify fiber network tools, components, and installations before use in real-time applications. It further enables leading manufacturers to build next-gen fiber optic products and services.

Accurate fiber optic measurements play an integral role in testing – validating and certifying that all components are built with high precision and specifications. Having correct measurements and specifications for fiber optic cables and wires is important because it helps maintain quality control, minimize distortions, and improve speed and reliability. Only high-quality fiber optic can help achieve faster and better results.

For accurate and consistent measurements, it is crucial to have a wide range of measuring tools that empower manufacturers towards building high-quality fiber optic cables and wires. CERSA MCI is trusted by some of the leading companies for their comprehensive range of devices designed specifically for fiber optic measurements and testing. High accuracy and high frequency, non-contact measurements are the essence of these devices. These further ensure comprehensive quality certification of the fiber optics right during the drawing process.

Here’s how fiber optic measuring devices can help in quality control, improved performance, and reduced costs of manufacturing:

- Inline Diameter Measurement and Defect Detection: The in-line instruments aid in fiber optic diameter measurement and allow monitoring fluctuations, as well as help, detect fine defects. These devices are widely used for accuracy, speed, identification & characterization of defects, and providing a display, records, analysis, etc.

- Inline Surface Detection: Modern fiber-optic measuring tools not only help measure fiber optic diameter and identify geometrical defects during the drawing or extrusion process but also enable measuring defects that may appear on the cable’s surface during the manufacturing process. Such defects may include scratches, lack of plating, or the presence of bubbles, particles, and impurities on the insulation.

- Offline Diameter and Ovality Measurement: Through continuous research and development, measuring devices now facilitate high precision fiber optic diameter and ovality measurement as less than 1 µm. The tools use diffraction technology to measure optical fiber thickness and ensure high accuracy as compared to shadow technology used commonly.

- In-line Full Quality Certification: These measuring tools provide some of the most important data to analyze – cladding diameter measurement, form bare fiber, spinning profile, tension, airline detection, etc. Furthermore, these allow technicians to measure defects in geometry, optical fiber diameter, etc. This data is recorded and analyzed to classify and sort the optical fiber and certify quality globally.

In addition to the above devices, premier fiber optic cable manufacturers use advanced software that allows obtaining important statistics, printouts, and analyses of the measurements. Powerful sensors help measure wire diameter and identify neckdowns and lumps in one product for larger cable and wire diameters.

Together, these devices and tools enable technicians to design fiber optic solutions with advanced functionalities, fewer defects, and superior performance in terms of lightning-fast speed, higher bandwidth, and frequency of data transmission and cloud storage.

Fiber optic system is the present and the future of the data transmission and cloud computing industry. Through efficient optical fibers measurement and testing, ensure having the best-quality fiber optic solutions that can further pave the pace for an Internet-driven world.