In the welding process, many types of metals and alloys are subjected to this practice. There are three types of accessible processes: the arc and the other two are direct and flux-core. Each type of welding process has a unique characteristic that makes it ideal for a particular kind of metal. Here are some more details about the three types of operation:

Arc is the process where hot gases or sparks are fed into a nozzle or gun. When a current is passed through the gases or sparks, a metal object is separated by the cutting or piercing process. Arc welding also works on both surface and internal processes. With the gas-arc welding, an electrode wire with an air-permeable tip (wet) or a non-wet electrode (dry) is used. This process uses both electricity and gas, gas is generally blown into the air and shot at the electrode tip to ignite the electrodes, which produces a fume which will allow the sparks to penetrate the sheet.

Flux-cored is also known as feed through welding. In this process, an electrode wire is fed through a metal tube called a flux core. The current passes through the metal tube and from the electrical surface of the rod to the torch. The rod is fed through the tube, and flux and gas become fused after the current passed. This process allows a continuous flow of current. This type of process uses two-metal flux-core rods that are fed with high voltage electricity.

MIG Welding

Welding MIG sheets together can be a complicated process. A common problem for MIG machines has not enough flux. Using the wrong amount of flux can cause both the flux and the metal to melt too much, ruin your workpiece or weld, and even damage your head! Instead of getting too much flux, the ideal flux level is too little flux. The key is reducing the melt to flowing flux ratio so that when the temperature starts to rise, it is already well past the point where it is likely to flow the flux.

There are two methods of MIG sheets. One is using two tanks of gunpowder with “flip-caps”. The flip-caps used for this technique must have a very low boiling point, reduce the chance of an explosion, and allow you to set the flux temperature without changing the metal’s melting point. The other method is to use two burners with oil. When you use this method, you need to be careful that the oil isn’t too hot, or else it will just scorch the paper being welded. It would be best if you also were mindful that the flare doesn’t get in the way of the paper. For this reason, this method is best for people who want to keep an eye on the work but don’t want to melt their workpiece.

MIG sheets are more comfortable than you might think, with the right knowledge. Before you get started, make sure that you are armed with the proper tools and expertise, visit here to read more.

Understanding TIG Welding

What is TIG welding? The short answer is that a welding process (learn more with Image Industries), is referred to as a laser method because the actual practice is done by laser. It was invented in the 1960s, but not many people know about it. A TIG machine that will be used to connect two pieces of metal will have to be placed under a strong amount of heat that will melt the pieces of metal and cause the flux to flow like a liquid. This fusion will form the weld, and once this is done, the two parts of the metal are now bonded.

However, the main type of method is not the only type of heavy equipment you can use for your work. There are many other types of welders that are available to work with the new and old ones. You can also choose between manual and automatic options for your machine to perform the tasks and which one you choose depends on how much money you want to spend and also if you’re going to use it for some personal or professional responsibilities. You can check out the internet for more information, and you can even visit different shops to get more information about the different kinds of welders you may need to use for your work.

In some cases, there will be problems with the metal sheets during the welding process, and this will require further tests and your welding equipment to see if it is possible to fix the problems. If not, you will have to find another site to get the metal sheet from the material used to make the weld. Remember that many different reasons might be the reason the welded metal sheet cannot be fixed and mixed in each type of welding.

Where to Start When Learning Stick Welding

When you get to your job site, there are a few things that should be considered when you learn about the stick process. It is not just the equipment that needs to be learned. It would be best if you learned how to safely and efficiently use that equipment to get the most of it.

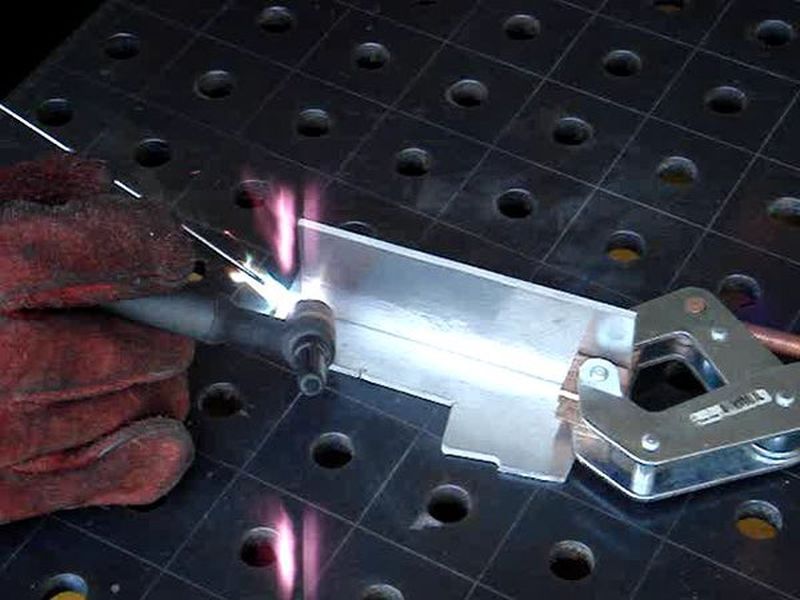

Stick is one of the most popular types of welding in the industry today. It is also one of the most dangerous as well because you are using a torch that is hot and can burn you if not used properly. The equipment you will need for this job is like a power tool, a torch, torch holder, and gloves. It does not matter what type of appliance you use. The torch is still one of the most important pieces of equipment for the stick process.

An excellent place to start when learning stick is learning the basics because it’s a lot harder than it seems, you have one chance to get it right or else you will have to redo the whole project. The first thing that you will need to learn is the different methods of welding. This includes the tungsten inert gas torch, or torch, and MIG machines. You will also need to learn about the different types of welds that you can make, including the blow torch, PTFE torch, plasma torch, and a flux. To get the best results, you will need to learn about the different things you can do with your torch. Some of these things include: change in wattage that you are working with, temperature, and duration.