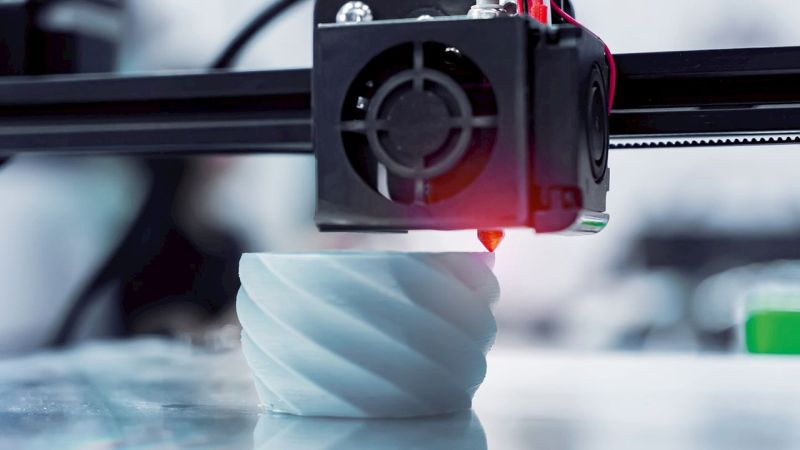

3D printing is a technology that takes a design from an idea to a physical, tangible 3-dimensional prototype object. 3D printing is also called Additive Manufacturing because the object is realized using an additive process where a material is deposited, joined, or solidifies layer by layer. The successive thin layers of materials such as a liquid molecule or powder grains are added pile after pile until the end product is obtained, thus the term additive manufacturing.

Companies such as Sculpteo based in San Francisco and Paris, are leading firms offering 3D printing services. For quality digital manufacturing materials, finishes, techniques, and superior optimization tools for file analysis and repair, look no further than Sculpteo 3d printing service.

The firm provides laser cutting services for market-oriented, on-demand production of prototypes. The manufacturing is both for individual products as well as short-run manufacturing.

Benefits of 3D Printing

3D printing technology was initially ideal for prototyping but is now rapidly embraced into essential production technology. Manufacturers and various industries are embracing 3D printing because it has significant benefits over the former manufacturing methods such as injection, molding, and subtractive.

1. Offers Flexible Designs

With 3D printing, you can obtain complex designs and print an object that traditional methods cannot. With the former manufacturing process, every new layer or change in part design needs a new mold, tool, or die to be made first so it can be used to create a new part.

However, in 3D printing, the product design is placed into slicer software, the required supports added, and then printed. No physical change is made in the equipment or the physical machinery.

Secondly, with 3D printing, it is possible to create and manufacture geometries involving hollow spaces within concrete parts. None of the traditional methods could produce this in part or at all.

In contrast to the former methods, 3D allows for multiple materials to construct a single product. The inclusion enables mixing and matching of textures and colors. It also improves the quality of the object because you can tap from a variety of mechanical properties.

3D printing allows users to edit designs. Even with limited CAD know-how, one can create unique, customized new additions to the product. Consequently, a particular design can come in a wide range of different materials.

2. Cost-Effective

With the traditional method, Metal Casting and Molding require a unique mold design for each part. The custom made tools came at a very high price. Thousands of these identical parts had to be manufactured to recoup the initial cost.

3D printing does not require specialized tools. This means 3D printing services do not come with extra startup expenses. The cost of 3D printing object depends on three things

- the amount of material used

- The time spent by the device to create the object

- Post-processing finish if necessary

3. Enhanced Prototyping Speed

3D printing is essentially used for form and function prototyping, which is completed in a matter of hours. Prototyping speed translates to better business because, within a short duration, several products are created.

Therefore, customers are presented with physical printing samples of the end product instead of leaving them to imagine what the final object will look like. This gives room for market testing and sampling, thus providing feedback from potential clients. And because of the risk of misunderstanding during communication is reduced, there is also minimal upfront expenditure for prototyping.

4. Guaranteed Quality

3d printing allows for layer by layer placement of material. This method ensures the production of better quality products. And since the main material in 3D printing is plastic, the parts are lighter than those made from metal. Lightweight property is particularly important in the aerospace and automotive industry.

Additionally, products can be made from other ideal materials other than plastic to realize heat resistance, water repellency, and durability properties.

5. Reduced Waste

3D printing is environmental-friendly because the creation of the product only requires the materials needed for the product itself, with reduced wastage compared to the traditional methods obtained from large non-recyclable elements.

3D printing also cuts down on the quantity of material required to complete an object. This translates to fewer shipments of raw materials across the globe, thus less environmental impact.

6. Affordability

The traditional process requires a significant set up of manufacturing systems. However, 3D printing costs much less to set up, making it much more accessible to small scale productions and micro-business firms.

3D printing does not need additional personnel to run, supervise, and maintain the printer because it is an automated system. This results in reduced operational costs than other manufacturing systems.

3D Printing Applications

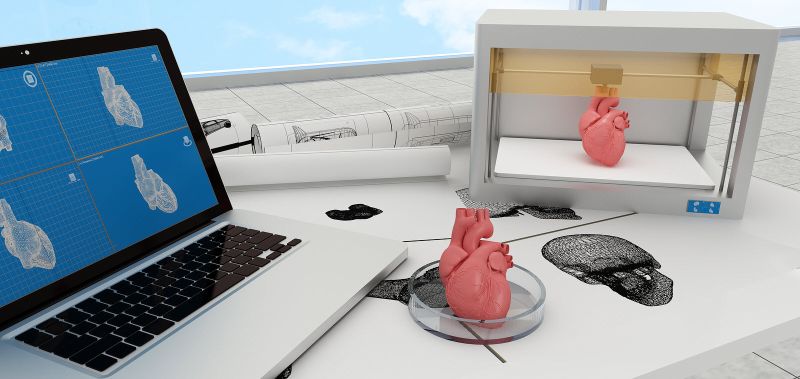

Healthcare

The medical sector is probably the greatest beneficiary of 3Dprinting services. It is being used to create human body organs such as the heart, liver, and kidney.

It is also being used to make dental care products such as dental crowns. It is further manufacturing knee and hip implants, orthotic insoles, hearing aids, and prosthetics.

This technology is growing to develop 3d tissue, bone, skin, and pharmaceuticals. Custom parts can also be made to suit individual patients.

With 3D printing, doctors can use tools created to follow a patient’s anatomy’s uniqueness accurately. Such tools are used in treatment involving the placement of screws, implants, and plates.

Automotive Industry

3D printing in automotive has gone beyond prototyping. Automakers are using the technology to create intricate, innovative designs that would otherwise not be possible with the traditional methods.

It is also being used to simplify part consolidation, a function where parts of a component are assembled into a single unit.

Other sectors that can benefit from 3Dprinting include;

- Aerospace

- Robotics

- Education

- Architecture and construction industry

- Beauty and jewelry making industry

- Consumer goods

- Sports equipment

In summary, 3D printing is moving from pure prototyping function to achieving numerous improvements in the production process. 3Dprinting is not just hype but a reality that will revolutionize all industries to enhance business growth across the globe.