Have you ever wondered why the metal products you buy always look so smooth and shiny? Well, the short answer is because of metal finishing. This process is used to apply a thin layer of coating to the product so that it is protected from the elements, corrosion, and it makes the piece durable, better looking, and if needed, unique. There are a lot of different processing techniques and depending on what should be achieved, the engineers can use one or several of them.

In this article, we are going to tell you more about the most popular and commonly used processing techniques for metal finishing and how they affect the end product.

Burnishing

source:metabo.com

For this procedure, steel balls are added to a vibrating machine and they are used to make the product’s surface brighter. The main goal of this process is to make the item better and more durable or to restore its original beauty.

Depending on the machine that is used for this technique, different types of smoothness and brightness can be achieved. It is mostly used for zinc products, but other types of metal can be polished as well.

Abrasive Blasting

source:azom.com

During this process, a stream of abrasive material is pushed against the product that needs to be finished. This treatment is used to change the surface of the product, and it can make it more or less rough. It can also be used to change the shape of it and to remove all the negative substances.

There are different types of blasting and the most commonly used is the sandblasting. The end result is similar to the use of sandpaper, but the whole process is faster and easier to complete.

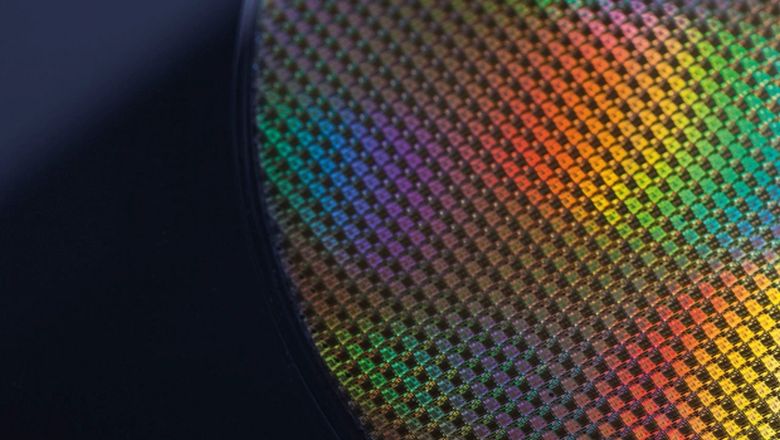

CMP

source:anton-paar.com

CMP or chemical-mechanical planarization is the process in which, as the name suggests two types of techniques are used to alter the material.

In this process, a rotating brush is pushed against the product, and chemical products are used to make the surface smooth and polished.

Polishing and Buffing

source:youtube.com

One of the most popular techniques for smoothing dents and bringing back the shine to all the materials. You’ve probably heard many times about the polishing procedure, as we all use it when we want to make our vehicles look better, and Shiny Smooth suggests that we use this type of metal finishing when we want to make our old jewelry look like it’s brand new.

Usually, an abrasive paste is used in combination with belts or discs that move against the metal, making it polished, smooth, and dent-free. If you are looking to get all the scratches removed from your car, then you should take it to a service that uses these machines.

The buffing process comes after the polishing and a rotating cloth wheel is used to remove all the lines that may show after the polishing.

Electropolishing

source:electro-glo.com

As the name suggests, during this process, electrolysis is used to give the product shine. Even though the process is simple and it consists only of the metal product being put in an electrolytic bath, it still has to be done by professionals.

This technique is used not only to give the products shine but to also smoothen out any imperfections it may have. It can be a part of the polishing procedure, but not every service or company combines these two techniques.

Vibratory finishing

source:directindustry.com

If you are looking for a way to clean or smoothen the rough edges of the material, then you should use this process. Commonly, small components are brightened with the vibratory finishing and the process is done in Vibratory Deburring Machine. You can check this if you want to know how everything looks and if you want to know more about the types of machines.

This process is preferred by many because the machines used are not as loud as others may be, and everything gets done fairly quickly.

Barreling

source:kernowcraft.com

As the name suggests, small metal parts are put in a barrel and tumbled so the surface will get smoother and shinier. It is not only used for new parts, but technicians also use this process to remove rust and burrs from older items that need to be cleaned or fixed.

Sometimes abrasives are used to make the whole thing faster and to ensure that everything will be done in the right way.

Metal Plating

In this process, the items are submerged in a chemical bath so that a thin layer of metal can be formed on the product. The reason why people go for this process is that it makes the product brighter, smoother and it can improve the look and durability.

This process is not used to make the surface scratch and dent-free and it cannot fix any defects that the item has.

Other processing techniques

source:industryeurope.com

It is said that there are a lot of different ways to make sure that the metal product is smooth, bright, and shiny. Depending on the type, size, and material used, the finishing engineer may use one technique only or combine several of them. For some of these processes, handheld tools are used, and others are done with the help of machines.

Other types of processes include:

- Industrial etching

- Thermal Deburring

- Linishing

- Grinding

- Powder Coating

- Hot Blackening

If you want your old metal items to be brought back to life, you can try doing that on your own, with a special abrasive paste and some cloths. In some cases, you will be able to remove the discoloration or rust. People try these DIY projects when they are looking to clean their jewelry or silver cutlery. You should always use protective gloves, masks, and goggles before you decide to do this, and you should do it out in the open so you don’t inhale any of the fumes.

In case you want your old vehicle or any other things to be restored, then you should contact a professional service that can do all of that for you fast and easy.

There are a lot of reasons why companies that produce metal parts do these things to their products before they sell them. The finishing makes items better, smoother, and brighter, but it also prevents corrosion and it makes them more durable.

With the right process, the item will have increased chemical, electrical, and tarnish resistance and it may even have a higher electrical conductivity.