Seals are an essential component of many products and play a crucial role in ensuring the quality and safety of products across various industries. From preventing the ingress of contaminants to protecting against tampering or counterfeiting, seals are used to maintain product integrity and ensure that products meet the highest quality and safety standards.

In this article, we will discuss the importance of seals in different industries and their various applications. We will also explore the types of seals used in different applications and the properties and requirements to consider when selecting the appropriate seal for a specific application.

The Role of Seals in Various Industries

Seals are critical in various industries, including automotive, aerospace, food and beverage, pharmaceuticals and electronics. In the automotive industry, for example, seals prevent the leakage of fluids, such as oil and coolant, from the engine and other components. Aerospace companies use seals to prevent air and fluid leaks in critical systems such as hydraulic and fuel lines.

In the food and beverage industry

Seals are used to prevent contamination and maintain product integrity. Seals are used in food packaging to prevent oxygen and moisture from entering and spoiling the product. They are also used to prevent bacterial contamination and maintain the freshness of the product. There are various seals offered on 123bearing for different food and beverage applications.

In the pharmaceutical industry

Seals are used to ensure the safety and efficacy of medicines. Seals prevent contamination, maintain product integrity and protect against tampering or counterfeiting. Seal selection must be carefully made to ensure compatibility with the product’s specific formulation and packaging requirements.

In the electronics industry

Seals protect electronic components from environmental factors such as moisture, dust and electromagnetic interference. Seals can also help maintain electronic device integrity by preventing tampering or counterfeiting.

The Importance of Seals in Product Quality and Safety

One of the primary functions of seals is to prevent the ingress of contaminants into a product. In the food and beverage industry, for example, seals prevent bacteria, mold and other harmful substances from contaminating the product. Seals also help to maintain product integrity by preventing leakage, which can compromise the quality and safety of the product. Seals are critical in the pharmaceutical industry, where contamination or leakage can seriously affect patient health.

Seals also play a critical role in protecting against tampering or counterfeiting. Tamper-evident seals indicate if a product has been opened or compromised. These seals are commonly used in the pharmaceutical industry, where tampering can seriously harm patients. Counterfeit products, such as fake pharmaceuticals, can also pose a significant risk to public health. Seals can help to identify genuine products and prevent the distribution of counterfeit goods.

Various seals are used in different industries with specific properties and applications. For example, seals may be made of materials resistant to high temperatures, chemicals or moisture in the food and beverage industry. In the pharmaceutical industry, seals may be designed to be tamper-evident, with features such as perforations or indicators that show if the seal has been broken. Seals used in the electronics industry may be designed to provide a barrier against electromagnetic interference or protect against moisture or dust.

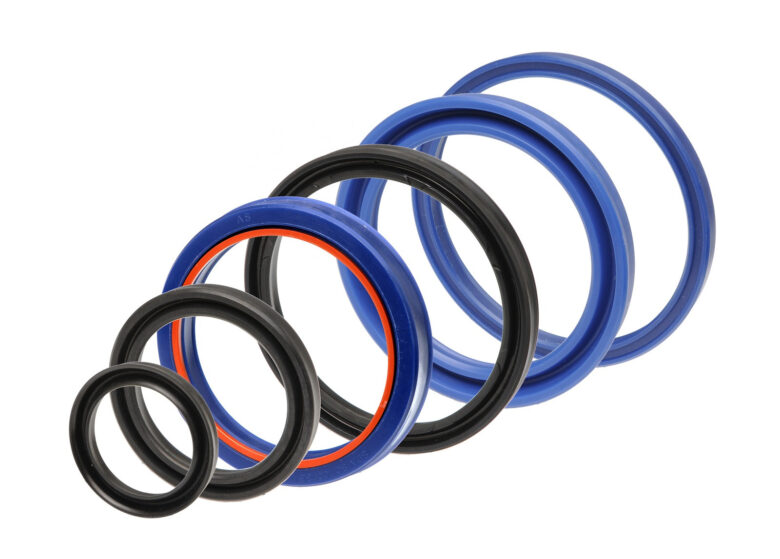

Types of Seals

Seals are used in various industries to prevent the leakage of fluids, gases, or even solids. There are different types of seals, each designed to suit different applications. Here are some of the most common types of seals:

Mechanical Seals

Mechanical seals are widely used in pumps, compressors, and other rotating equipment to prevent leakage. They consist of two sealing surfaces in contact with each other and held together by a spring. The mechanical seal forms a barrier between the pumped fluid and the external environment.

O-Ring Seals

O-ring seals are among the most commonly used in hydraulic and pneumatic systems. They consist of a circular elastomer ring compressed between two parts to create a seal. O-ring seals effectively prevent fluid leakage and can withstand high pressure and temperatures.

Lip Seals

Lip seals are also known as oil seals and are used to prevent the leakage of oil or other fluids from machinery. They consist of a flexible lip that contacts the rotating shaft and a metal case fixed in the housing. Lip seals are commonly used in gearboxes, engines, and pumps.

Gasket Seals

Gasket seals are used to create a static seal between two surfaces. They can be made from various materials, such as rubber, cork or metal and are used in multiple applications, including piping, engines and compressors.

Diaphragm Seals

Diaphragm seals are used in pressure measurement and control systems. They consist of a flexible diaphragm in contact with the measured fluid, separating it from the measurement device. Diaphragm seals are commonly used in chemical processing, food and beverage and pharmaceutical industries.

Materials Used in Seals

The choice of material for a seal depends on the specific application requirements, such as temperature, pressure, fluid compatibility and operating environment. Here are some of the most common materials used in seals:

Elastomers

Elastomers are rubber-like materials commonly used in seals because of their flexibility, durability and chemical resistance. Examples of elastomers include nitrile rubber, silicone rubber and fluorocarbon rubber.

PTFE (Polytetrafluoroethylene)

PTFE is a synthetic fluoropolymer with excellent chemical resistance and is commonly used in seals for aggressive chemical applications. It is also resistant to high temperatures and has a low coefficient of friction.

Metals

Metals such as stainless steel, brass, and aluminum are commonly used in seals for their strength, durability and resistance to corrosion. Metal seals are used in high-pressure and high-temperature applications.

Ceramics

Seals use ceramics for their hardness, wear, and chemical resistance. They are commonly used in applications that involve abrasive fluids or high temperatures.

Composites

Composite materials such as carbon fiber-reinforced polymers (CFRP) are used in seals for their high strength-to-weight ratio and resistance to wear and corrosion. They are commonly used in the aerospace and defense industries.

Conclusion

In conclusion, the importance of seals in the industry cannot be overstated. They are critical in ensuring product quality and safety across various industries, including food and beverage, pharmaceuticals and electronics. Seals are vital in preventing contamination, maintaining product integrity and protecting against tampering and counterfeiting.

The appropriate seal for a specific application is essential to maintain the highest quality and safety standards. As industries continue to innovate and develop new products, seals will remain a crucial aspect of product design and manufacturing. Companies must continue investing in research and development to use the most effective and efficient product seals.