We learn from an early age that color enhances the visual experience. The printing industry understands this facet of life, too, as studies show that color media increases interest in printed material by at least 40%. Commercial printers, whether they are digital or traditional, typically use the 4 Color Printing scheme to bring colored images and text to paper. This post takes a look at how the dynamic process of Four Color Printing works.

How is CMYK Printing Used?

The 4 Color Process is the most widely used color system by commercial printing businesses for creating multi-colored photographs and designs. The method is utilized for creating catalogs, brochures, books, magazines, postcards, and other printed items that contain full-color images.

Additionally, commercial printing businesses use CMYK printing in digital and offset printing. Digital printing is used more for small jobs and those which require a quick turnaround, while offset printing, otherwise known as lithography printing, is excellent for companies that need multiple high-quality copies of their most vital sales brochures and other materials. Lithography printing is a good deal cheaper than digital printing or toner-based for larger quantity runs.

Benefits of the CMYK Process

CMYK Color Printing, also known as Four Color Printing and Full Color Printing, is popular in the commercial printing industry. Here are some of the main drivers that put Four Color Printing in such high demand:

1. Cost-effectiveness: The printing process is very cost-effective, especially when compared to larger orders that use tone-based printing.

2. Impressive results: Black and white colors are nowhere near as awe-inspiring as vibrant colors splashed across pages.

3. A wider range of colors: The CMY portion of CMYK covers most of the lighter color ranges more easily than those in RGB. However, CMY can’t generate true black, so the “K” in CMYK is the black added to achieve it. In essence, this results in a much wider range of colors compared to the RGB seen on the screens of digital devices.

How the 4 Color Printing Process Works

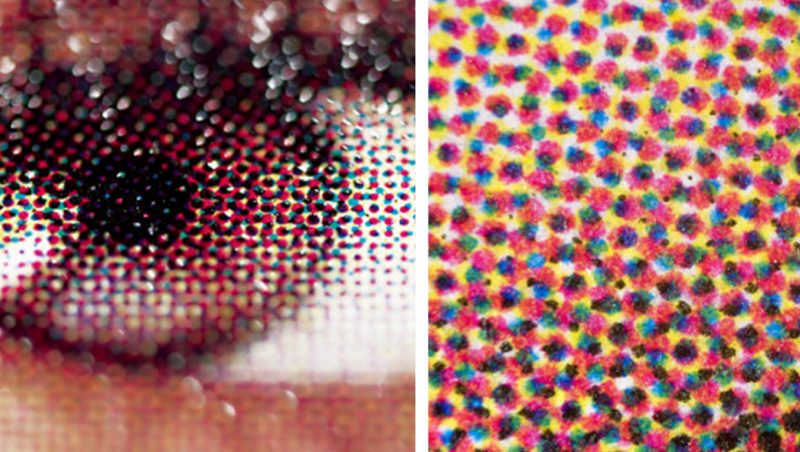

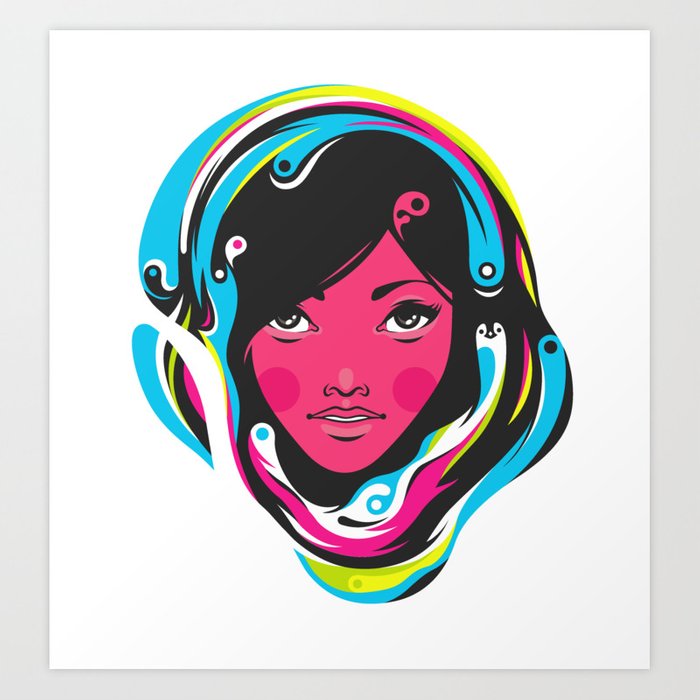

In commercial printing, the 4 Color Process includes the use of four printing plates: Cyan, Magenta, Yellow and K, which stands for Keyline (Black). The CMYK artwork that customers supply is separated into these four hues by printers, with one plate per hue. The CMYK inks are then applied one by one to the four different rollers in the machine, as the paper is fed through the printing press. The hues are then applied to the stock one by one, and, finally, the full-color result comes out of the printer.

How CMYK Printing Renders Color

If you didn’t know anything about how color is mixed for printed media using CMYK, you’d most likely think that the rainbow of hues that commercial printers produce are achieved by using primary colors – and that the mixing of these primary colors gets secondary colors. Sort of like mixing red and yellow on a palette with your paintbrush and getting the resulting color, orange.

However, the technology that brings printed visual candy to paper in the Four Color Process operates in a slightly different manner than it does when applying paint to canvas. In fact, there is an old running joke that demonstrates how different the process is by saying, “You want to print black and white? That’s too bad because you are out of yellow!”

One feature with CMYK Printing is that the same standardized base colors are always used. A CMYK printer uses light-absorbing CMY inks, whose hues are mixed using halftoning, dithering, and other optical techniques. To render color on paper, Full-Color Printers use reflected light and subtractive color inks. Below are a few CMY combinations that result from the process:

- (C) Cyan absorbs Red, which leaves Green & Blue to produce Cyan

- (M) Magenta absorbs Green, which leaves Yellow & Red to produce Magenta

- (Y) Yellow absorbs Blue, which leaves Red & Green that combine to produce yellow.

A blank sheet of paper that doesn’t have any colorants or dyes added to it will appear white because of the wavelengths of light reflecting away from it. Adding CMY ink absorbs these wavelengths to produce different colors.

- Printing Cyan and Magenta together makes Blue.

- Printing Cyan and Yellow together makes Green.

- Printing Yellow and Magenta together creates Red.

- Printing Cyan and Magenta and Yellow in equal quantities blocks all colors to produce Black.

- As more ink is added to the process, the hue gets darker.

The Limitations of RGB Design and Printing

Many people design in RGB, but print with CMYK, which isn’t always advisable for reasons explained here. Designing and printing in RGB (some printers print in RGB, for the record) is even worse since RGB creates color by layering RGB colors, which are already dark to start with. This effect makes it extremely difficult to produce lighter colors such as lime green and yellow.

With the CMYK process, the original colored image is segregated into four different color values by the use of screens and filters. Software programs such as Adobe Photoshop, Corel Draw, or Microsoft Publisher performed this process digitally.

The RGB colors seen on the screen are then separated into CMYK colors. The color separation is then transferred to four CMYK printing plates and printed on a printing press with CMYK ink to closely reproduce the original digital color image. Small dots of colors are printed at varying angles to generate the printed image.

Although RGB has a massive range of hues, they can vary widely from PC screen to mobile to final print. Unfortunately, this means when you convert to CMYK, there’s a good chance that your printed hues won’t always match your original intentions.

Why CMYK Color Design is Best

Whenever the CMYK process lacks all the possible color combinations, the closest hues to them are selected during the print job. Unfortunately, when you print an image that has been designed in RGB mode, it typically comes out looking discolored or faded when converted to CMYK for print. In the end, the beautiful custom poster you designed for printing will look different on paper when compared to how it looks on your computer.

To prevent discoloration, you will have to account for this with color management methods. Designers get around this issue by designing in CMYK, ensuring that the colors they use are printable. It’s crucial to bear this in mind when undertaking digital or offset printing tasks.

Why it’s Essential to Manage Color

Some designers discount color management and still wind up with acceptable colors in their printed pieces. That is more likely a sign of good luck or the fact that the print is “acceptable” enough to be used for some low-priority printing jobs such as homeowner association flyers or company picnic bulletins.

On the other hand, if you care about getting consistent, precise results and want to make an excellent impression on your audience, then you’ll definitely want to pay attention to color management when creating and printing your collateral.

The Wrap Up

Factors such as CMYK, RGB, process, spot, the quality and type of digital device, and even the paper used, can all make a difference in what you view on-screen vs. what shakes out in the printed copy. That’s why it’s important to use proper color management to closely match what you see on the screen to what you see printed.

CMYK printing will be the dominant model for quite some time, as it is cheaper and has a wider spectrum of color options than RGB does. All sorts of factors make a difference in what you view on-screen vs. what results in the printed copy, so, at a minimum, a designer needs to have excellent color management skills to produce professional-looking prints.

Make a Better Impression with CMYK Printing Services

Printing companies are used to all factors that influence the finished printing product, and have the expertise and equipment needed to yield high-quality results. For the next printing project for your business, be it brochures, multimedia packaging printing, or newsletters, it may be a good idea to either relinquish the CMYK process to them, or let them work with you to get the most cost-effective and aesthetically pleasing color results you want.

Craig Sheer is the owner of Sheer Print Solutions, located in Soho, NYC. We are the proven leader for affordable, high-quality Digital and Offset, and Large Format Printing in NYC. Sheer Printing Solutions is your single source for solutions to all your printing, binding, warehousing and fulfillment needs.