Flexography is a process used in many different industries for printing labels, product packaging, and many other types of prints. You’re surrounded by the products of flexographic printing even if you don’t know it yet!

So, what is it exactly and how does it work? How can it benefit your business? Where is this technique applicable? Is it cheap or expensive? How to choose the right flexographic services for your specific production needs?

Keep on reading to learn the answers to these questions and more! So, without any further ado, let’s get right into it!

A step-to-step guide to flexographic printing

1. The designing phase

Image distortion is the biggest obstacle you’ll encounter when you’re designing your artwork for flexographic purposes. Calculating the right dimensions can be quite challenging, so it’s often better when it’s left to the hands of professionals who know how to properly use the designing software. Of course, this doesn’t mean you’re not allowed to be involved in the creative process: just make sure you’re communicating your aesthetic needs properly!

2. Feeding the materials

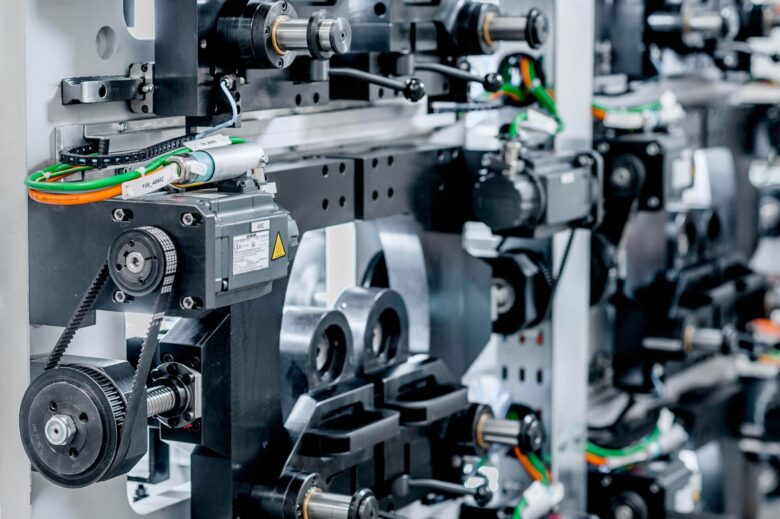

After you’ve made your unique artwork, it’s time to choose and feed the materials into your flexographic press. This type of printing supports almost every type of substrate material: be it metallic, plastic, cellophane, or paper, which is why it’s so popular in the first place. The materials are web-fed to the machine for a quick and continuous printing process.

3. Choosing the right colors

Most flexographic printers come with preset options that can then be used to create unique colors and patterns. Again, this requires careful planning and knowledge of relevant computer programs. Make sure you do some research and choose high-quality software solutions for the best results.

4. Drying the ink

After the printing is done, all that’s left to do is to wait for the ink to dry. Be careful, though, as the ink used in flexo printing isn’t anything like what you find in your regular office printers. It’s UV curable, which means it can’t dry in the air. Instead, make sure you use ultraviolet light to cure them properly.

5. Cutting

Due to the continuous printing technique used in flexo printing, you’ll need to separate the labels by cutting them. The cutting die is made specifically for this type of printing, which allows precise and meticulous separation to keep your labels identical in size.

The advantages of flexographic printing

If you’re wondering whether this printing method is suitable for your business needs or not, we bring you the potential benefits to let you decide for yourself!

- It’s extremely fast- Flexographic printers can print close to 7km per hour of labeling material. That makes them extremely convenient for mass-production of all sorts. If you need large quantities of printed material, flexography might be the fastest solution out there.

- Versatility in terms of base materials- As we’ve mentioned before, this printing method doesn’t limit you to one type of material, which is incredibly important for some specific industries.

- Low ink costs- Compared to its most common alternative (digital printing), the ink used for flexographic printing processes is much cheaper, especially when it comes to massive volume runs.

- Advancing technology- even though flexography has been around for some time, the technology seems to be advancing and adapting to modern needs and trends: it’s unlikely to become outdated any time soon!

The disadvantages

Just like every other printing method available, flexography comes with its unique drawbacks. Whether the benefits can outweigh those disadvantages is on you to decide.

- Flexo printing plates are expensive- these plates are relatively expensive compared to their alternatives, but they also provide longevity if properly cared for.

- Too expensive for small projects- again, this type of printing is more suitable for bigger production projects: small-scale printing is simply too expensive. Of course, if you have plans to broaden your product line in the future, then investing in flexographic solutions can still be a good business call.

- Requires knowledge and training- Operating these printers and using their complex software can be quite challenging for a newbie. Make sure you’re well-prepared before you start your flexographic projects.

Maintenance

Overall, flexo printers and other relevant equipment are quite low maintenance. However, if you’re aiming for your investment to be a long-term one, you should learn how to properly care for your machinery. That especially goes for your flexo sleeves, which are a particularly sensitive part of the equipment that should be properly stored and managed. Make sure to invest in a flexo sleeve storage system such as those found at FlexStor, that will keep the sleeve performance long-lived and at high-quality levels.

Besides that, make sure your staff is handling the entire printing system with proper care by providing them with relevant training. Keep your user manual close to you at all times, and remember to inspect your equipment regularly.

Flexo vs Digital

The main question everyone asks when considering between flexo and digital printing solutions has to be: “Which one is more cost-effective?” Well, unfortunately, there are no right answers to that question. It all boils down to your specific needs and preferences, as well as your long-term business plan. Flexo is better at high volume orders, and that’s when it becomes the most affordable solution. On the other hand, digital is better for smaller and less frequent printing projects, as it doesn’t require the use of printing plates.

Overall, your choice depends on the volume of your orders and your printing schedule. If you’re unable to decide between the two, make sure to check out hybrid printing techniques instead.

Wrapping it up

In this article, we’ve tried to cover some basic information about flexography printing, its pros and cons, and how it compares to its most popular alternative: the digital printing method. Talk to an industry professional to get more detailed information before you incorporate the technique into your own business.

Overall, we hope we answered some of your questions about this incredible printing method, and we wish you good luck in your further research!