Drilling and placing piles date back to the earliest times. Even former pile-dwellings in prehistoric times had wooden piles. Of course, everything was done manually and took a long time. Today it is more modern and technology has advanced a lot – so drilling and installation of piles have become more accessible than ever. We will introduce you to the equipment and machines used when drilling and installing piles and protective fences – and even solar panels.

What Are Piles And How Are They Placed?

Before starting to make drilled piles, it is necessary to perform some preparatory work – which includes appropriate work on the construction site. Also, there are jobs related to the selection, delivery, and installation of equipment. Everything must be done under the specific project and field conditions.

Preparatory works on the construction site include the construction of working plateaus – and the construction of access roads, for the movement and operation of the planned drilling equipment. It also includes the delivery of reinforcement baskets and concrete for concreting piles. Mechanization and equipment for quality and efficient work for the production of drilled piles consist of the following:

- Excavator for excavation with appropriate tools

- Protective pipes

- Hydraulic tubular oscillator for rotational oscillation of protective tubes, which facilitates its pressing into the ground

- Crane for removing protective pipes and lifting and adjusting the armature basket

- Contractor concreting equipment

These are just some basic things we need to adhere to when drilling and installing piles in a building.

Technology And Method Of Making Piles

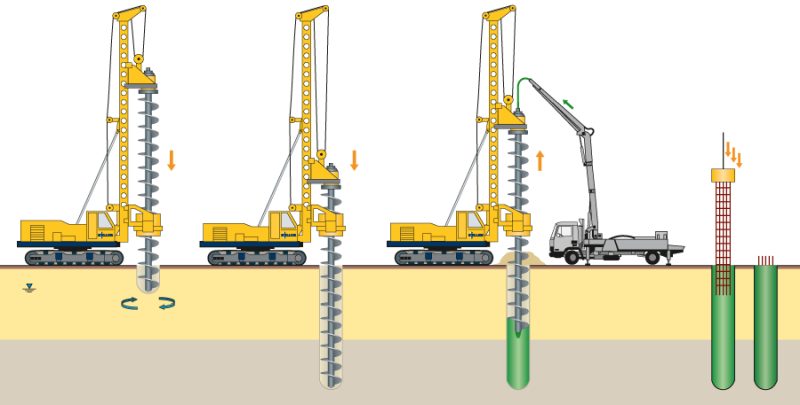

The technology of making drilled piles consists of three basic phases:

- From digging a well, or drilling

- From making and installing the armature basket

- From making concrete and concreting piles

As already mentioned, the excavation of wells in the construction of drilled piles in supporting structures – can be with full pipeline or with the partial pipeline. The beginning of drilling requires the placement of an auxiliary pipe in the place of the well – which serves to ensure the position and direction of the pile.

After driving in the auxiliary pipe – the excavated soil is excavated and transported from it. Drilling is performed when the projected bottom is reached – which is controlled by two to three consecutive measurements of the borehole height, with a graduated strip.

Types Of Piles And Where Everything Applies

The usual materials for making the pile are wood, reinforced or prestressed concrete or steel. Wooden piles are relatively light, easy to transport and manipulate – and in some countries, they are very affordable. They can be mounted to a depth of about 18 m – and can be extended and continued. They are generally installed below the groundwater level – and then their durability can be significant.

However, above the groundwater level, they must be protected with impregnating agents. In seawater, they can also be damaged. However, in modern living conditions – concrete is the most widely used. The length of the piles is determined in advance. Piles are made in controlled conditions and transported to the place of installation. If special connections are continued, the longest reinforced concrete element is up to about 15 m long. Therefore the depths of up to 100m can be achieved.

However, in most practical cases, the depth of mounting is not more than about 30 m. Mounted piles concreted in the ground are set under the protection of the previously installed steel pipe – which, after reaching the desired depth, is successively pulled out of the ground with the addition of concrete.

Pile Driving Equipment And Machines For Protective Fences

Depending on the work you do and for what purpose you need piles, the equipment and machines that you will use in your work also depend on that. According to International Attachments, there is also equipment that has been modernized for the installation of solar panels – so it is much easier for installers to install and speed up the installation process. We will introduce you to several examples of equipment and machines for driving cuttlefish and protective fences.

1. Pile Breaking Machine

The benefit of some newest machines for drilling is a compact but stable design that is made in a combination with strong and highly-durable elements – such as rotating heads or some special cables. Additional functions are utilizing some specially made supports with telescopic lower machines, a kinematic parallelogram, a rotating winch, hydraulics, and an electrical system of controlling – as well as detachable counterweights for weight reduction due to transport. The position of the winch on the pole is perfect for the drilling procedure, and cable wear is reduced to a minimum. Advantages and features:

- Good, reliable design

- It is based on the hydraulics

- It has a telescopic movement of the base width – caterpillars

- It has high-performance, strength, and also stability while working

- Winches that are attached to a pole

- High universality

2. Kelly Rods And Tubes

Some companies offer a wide range of drills. Kelly rods, a telescopic drill pipe, works on the principle of torque transmission and prestressing of the drill. Kelly rods and drill lengths reach the maximum depth available. And they are also used for very inaccessible terrains where a protective fence is installed.

Choosing the right Kelly rods machine depends on:

- Drilling depths

- The inner diameter of the rotating head

- The outer diameter of the connecting part

3. Rotating Heads And Double Rotating Heads

The characteristics of this system compared to conventional twin-head rotating systems are that the upper rotary head can be removed independently of the lower rotary head. The DDK system has won the award for the best innovation at various trade fairs, and with the help of this machine you can mount it at great depths, so you can use it in various jobs around piling piles and large protective fences.

4. Pile Driving Navigation System

Today, a variety of equipment can be found on offer – and it offers a variety of compact solutions, such as a navigation system to suit any hammer model. These machines are light, but still very stable. Interchangeable parts allow easy adjustment. The navigation can be attached to any crane model with the appropriate capacity. Since the inlet is not connected to the upper transmission of the crane – it can be rotated 360 around its vertical axis. These models are used for driving piles at great depths and are often used for waterworks.

5. Solar Panel Mounting Machines And Equipment

These machines are easy to handle and come in multiple models. They are used as a panel transmitter so that the panels are not damaged – but also as a panel drives into the ground. They are very useful because they are easy to guide and speed up the panel assembly process.

The Bottom Line

We hope we have helped you decide if you need pile driving equipment or guardrail machines. In any case, the decision to buy these machines should be considered – because owning such equipment is a very lucrative job in construction, and you can rent them to other construction companies.