Whatever the scale of a construction project, quantifying and costing the materials, labor, and equipment required is a vital procedure that is pivotal for budgeting and cost control.

Quantifying and costing is particularly important when projects are put out to tender, and is formalized in a bill of quantities (BOQ) which enables contractors to quote on equal terms. Then, when the tender has been awarded, it is used together with the project schedule as a tracking tool for cost planning and cost control.

The best way to track all the ongoing activities of each employees on a project tracking platform, which can help overseeing the construction project. You can access one here.

Ultimately, a BOQ coupled with an accurate cost estimation will help with accurate project planning and will contribute to a reduction in the time and costs of any construction project. It is also an excellent tool for evaluating and comparing different products required for projects.

The bill of quantities is usually prepared by a quantity surveyor or a cost consultant with experience in the field. More often, an engineering firm like

Elements of a Bill of Quantities

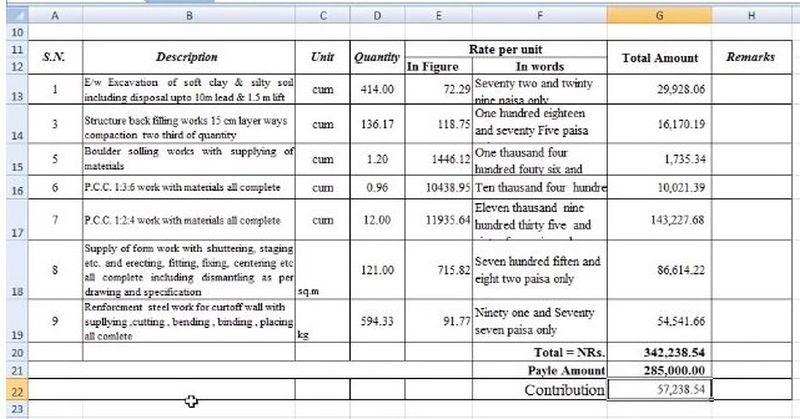

Everything that is required to build or fabricate items for a project need to be included in the BOQ. It literally breaks down requirements item by item and provides quantities based on the agreed specifications. Costing and quoting (or more formally, tendering) can then be done on an equal basis.

Generally, the project will be categorized into different areas of design and construction that require the services of different professionals and tradesmen. Typically these are:

- Architectural

- Structural

- Mechanical

- Electrical

- Plumbing

- Communications

- Security

- Fire protection systems

In each of these, the list of work and materials required will need to be specified in infinite detail.

Even a BOQ for fairly straightforward single-story dwelling would include most of these categories. Here is an example that illustrates how detailed quantification needs to be for just such a house constructed from bricks and mortar. It presupposes that all the planning and design work has been completed by the various professionals including architects and engineers.

- Preliminary and general issues that include things like site clearing, soil tests, connection fees for water, electricity, gas, and so on, tender fees, plant and equipment to excavate as well as site offices, tools, scaffolding, and general expenses including insurance. This will include materials and supply and fit costs but no labor cost.

- Earthworks and excavation which will involve material, labor, and equipment costs. Fill might be needed under the surface bed and foundation trenches may need to be excavated.

- Concrete works including the materials for foundations, concrete lintels, and the labor to mix concrete and place it. On larger sites, ready-mixed concrete is commonly delivered to site in large trucks.

- Brickwork that includes the bricks, the mortar to lay them, the labor, including skilled bricklayers, and various sundry materials.

- Door and window frames that might be steel or wooden.

- Roof timbers and roof covering materials and any labor required to install the roof. Everything from the roof underlay to insulation needs to be included unless there is a separate list that handles all insulation needs.

- Plaster and screeds for walls and floors. Materials and labor must be quantified.

- Floor coverings including carpets, which are normally fitted by a specialist company. Tiles will usually be considered separately.

- Ceilings that might be made from gypsum board or tongue-in-groove timber. These are often supplied and fitted by a specialist company rather than installed by the contractor.

- Glazing for windows and possibly sliding doors.

- Painting of all the different internal and external surfaces. Quantities need to be carefully calculated in terms of the specifications. There are usually a variety of different paint and related products, like wood sealers, as well as sundry materials like filler, sandpaper, and turpentine for cleaning paint brushes and rollers if oil-based paints rather than water-based products are used.

- Built-in cupboards including kitchen units that might be ordered from an outside company on a supply and fit basis.

- Woodwork and ironmongery including doors, skirting boards, quadrant beading, door handles, and locksets.

- Tiling which might include both floor and wall tiles, especially in bathrooms and kitchens. Specialist tilers will normally be sub-contracted for the job.

- Plumbing, which is a major construction specialization, involves rainwater goods including gutters and downspouts, all the equipment and fittings for water supply and drainage, and everything needed for bathroom and kitchen fittings and fixtures. Supply and fit costs are usually substantial because of the work involved.

- Electrical infrastructure and wiring including supply cable, plug, stove, and light points all need to be factored in and listed in the BOQ, regardless of how basic it is. An electrical company or specialist will usually be contracted to do this part of the build, though this will only be decided once the tender process is complete. Light fittings and fixtures might be added to electrical.

- Heating, ventilation, and air-conditioning (HVAC) systems that have been designed by professional firms or specialist engineers.

- Communications, which might include an inter-com system, telephone points, doorbells, and a point for television.

- Security systems that might include alarms and other automated systems as well as fire protection systems.

- External site works including removal of building rubble and work like paving, washing lines, and possibly a garden shed.

In addition to the detailed lists that quantify everything, there are often some prime costs (P.C.) and provisional sums that are added.

Advantages of a BOQ in Construction Projects

A BOQ is part of the standard procedure for construction projects because of its many advantages. The BOQ:

- Simplifies tenders because everybody is dealing with exactly the same items.

- Is a fair process because a neutral party, the cost consultant or engineering firm, determines what is required and all contractors bid under equal conditions.

- Speeds up the tender process because the basic requirements are spelled out for all competing contractors.

- Improves accuracy because the quantities and measurements involved in the project are all determined beforehand and included in the BOQ.

Even though several contractors compete during tender processes, the lowest bid doesn’t always win and it can help to avoid lowballing, which is when contractors tender at prices that are unnecessarily low.

Some companies like to divide BOQ documents into a series of smaller documents so that, for example, plumbing and or electrical jobs are considered separately.

A BOQ may also be generated with building information modeling (BIM) software allowing the BOQ to be updated automatically if design changes or additions are made.