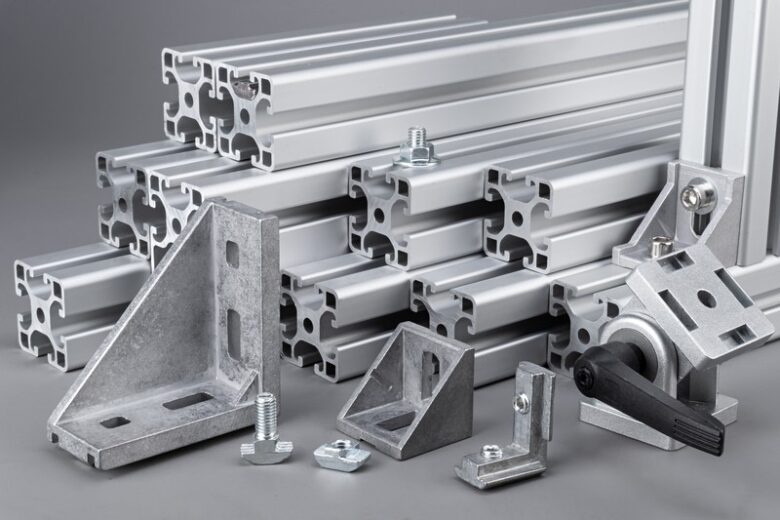

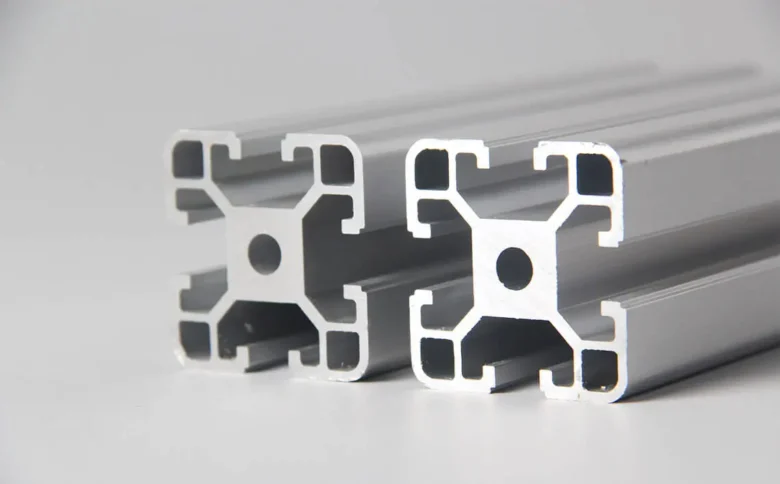

Aluminum extrusion is a manufacturing process that offers numerous benefits for a wide range of industries. It involves shaping aluminum material into various profiles through a process of heating and forcing it through a die. The resulting shapes can then be used to create custom designs and cost-effective solutions for a variety of applications. This method is highly versatile and allows for the production of intricate shapes with tight tolerances, making it a popular choice for industries such as construction, automotive, aerospace, and electronics.

In addition to its versatility, potash extrusion is also a cost-effective solution for many applications. The process is highly efficient, with minimal waste and low tooling costs, making it an economical choice for both small and large production runs. At hjaluminumwindow.com, they have been able to pass these cost savings on to their customers. In this article, we will explore some of the key benefits of aluminum extrusion and how it can help businesses achieve their goals efficiently and effectively.

1. Custom Designs

The unique properties of aluminum make it an ideal material for the aerospace components manufacturing sector. The specific nature of this market doesn’t permit the mass production of generic parts. Moreover, the custom-demand, precision-oriented components often require exact specifications and stringent quality standards. With this in mind, aerospace components manufacturers such as AST depend significantly on the adaptability of aluminum to manufacture tailor-made parts that meet the specific needs of the aerospace industry.

One of the most significant benefits is the ability to create custom designs that meet specific requirements. With the extrusion process, it is possible to create a vast range of shapes and sizes. This means that potash extrusions can be customized to meet the exact specifications of a project. In addition, the extrusion process allows for the creation of complex shapes, which may not be possible with other manufacturing processes.

2. Advantages of Custom Design

Custom designs offer several advantages over standard designs, particularly in the manufacturing industry. Custom designs allow for a higher level of personalization, enabling businesses to create products that better meet the specific needs and requirements of their customers. This can result in increased customer satisfaction and loyalty, as well as a competitive advantage in the market.

Custom designs can also help to streamline manufacturing processes, as products can be designed to fit within existing production systems, reducing the need for costly modifications. Additionally, custom designs often result in improved product performance, as products are designed to optimize efficiency and functionality for specific applications.

From a marketing perspective, custom designs can be an effective tool for brand differentiation. Custom products are often seen as premium products, and can help to create a distinct brand identity that sets a business apart from its competitors.

3. Cost-Effective Solutions

Aluminum extrusion is a cost-effective solution for many manufacturing projects. The process is highly efficient, and large volumes can be produced quickly and at a low cost. This is because the extrusion process eliminates the need for multiple manufacturing steps, such as welding and assembly. Additionally, the use of extrusions is highly cost-effective as the material is lightweight, which reduces transportation and installation costs.

4. Comparison to other manufacturing processes

When compared to other manufacturing processes, aluminum extrusion offers several advantages. Unlike traditional machining or casting methods, aluminum extrusion allows for the creation of complex shapes with precise tolerances, resulting in higher levels of accuracy and consistency. Additionally, aluminum extrusion is a highly efficient and cost-effective process, with the ability to produce large quantities of parts quickly and with minimal waste. Compared to other forming processes, such as stamping or forging, aluminum extrusion can be used to produce parts with thinner walls, reducing weight and material costs. Overall, the versatility, efficiency, and accuracy of aluminum extrusion make it a valuable solution for businesses across a range of industries.

5. Strength and Durability

Another significant benefit of potash extrusion is its strength and durability. Aluminum is a highly durable material that can withstand a wide range of environmental conditions, making it ideal for use in a variety of industries.

The extrusion process further enhances the strength and durability of the potash by creating a seamless and uniform material. The extrusion process allows for the creation of profiles with consistent and predictable mechanical properties, resulting in products that are highly reliable and consistent in performance.

The strength and durability of aluminum extrusion also make it an ideal choice for products that require high precision and tight tolerances. The extrusion process enables the creation of products with complex geometries and precise dimensions, making it an ideal solution for applications such as automotive frames and aerospace components.

6. Lightweight

One of the key benefits of aluminum extrusion is its lightweight nature. Aluminum is a lightweight material, with a density of approximately one-third that of steel. This makes it an ideal choice for applications where weight is a concern, such as in the aerospace and automotive industries.

The lightweight nature of potash extrusion has several advantages. Firstly, it allows for the creation of products that are easier to transport and handle. This is particularly important in industries such as aerospace, where weight reduction is critical to improve fuel efficiency and reduce emissions.

In addition, its lightweight nature makes it an ideal choice for products that require high strength-to-weight ratios. Aluminum is a strong material, and when combined with the efficient manufacturing process of extrusion, it can provide products with exceptional strength and durability, while remaining lightweight.

Its light weight reduces the amount of labor required for installation, making it a cost-effective solution for many applications.

7. Recyclability

Aluminum is 100% recyclable, making it an environmentally friendly material. The recycling process requires only 5% of the energy needed to produce new aluminum, making it a highly sustainable option. Additionally, the use of recycled potash in the extrusion process can reduce costs, making it an even more cost-effective solution.

Conclusion

In conclusion, aluminum extrusion is a highly versatile and cost-effective manufacturing process that offers numerous benefits for businesses in various industries. From custom designs to precise tolerances, aluminum extrusion allows for the creation of complex shapes and profiles that meet the specific needs of different applications. This process is not only efficient and affordable but also sustainable, making it a smart choice for businesses looking to reduce their environmental impact. With its many advantages, aluminum extrusion is a valuable solution for companies seeking to improve their products, increase efficiency, and stay competitive in today’s market.