CNC machining is one of the important factors to produce high-quality metal and plastic machining parts. By using the best machining, metal and plastic companies are able to produce precise and high-quality products needed by most of the end users. A specific service such as artmachining.com helps to do the machining process to meet your company need.

The Process of Creating a Precise CNC Milling

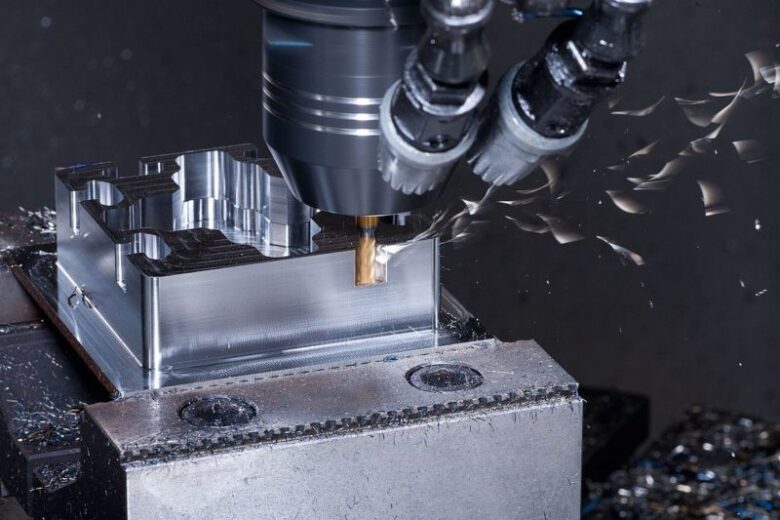

CNC milling and turning is a process to shape a material just like what the end users want. The shaping process is using rotary cutters and it uses to remove the material from the stock along a single axis. The final product is a part that meets the need of the end users. The artmachining.com combines the latest CNC milling and turning processes with proprietary technology to produce high-quality parts. Plus, it uses advanced software to control the equipment based on the specification of the product design.

The Benefits of CNC Machining

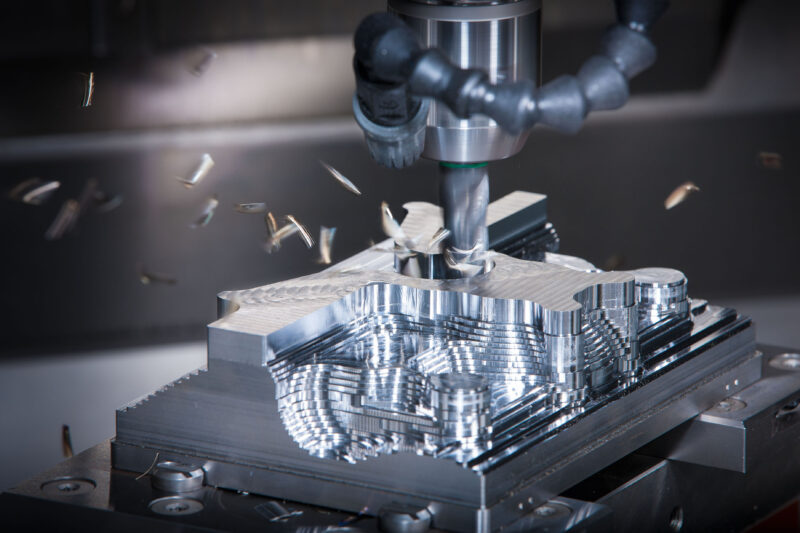

CNC milling and turning are a flexible process which can be applied for any material, especially metal and plastic. Moreover, the combination of the latest technologies and techniques provide a fast tooling process. Actually, the users don’t have to spend too much money only to use this machining because it is a low-cost process per unit. CNC machining also gives benefits for prototype industry. This milling process helps to create high-quality prototypes every day faster, easier, and more precise.

One of the issues in the machining process with old-fashioned technology is the way to remove the metal material. Nowadays, it is not a problem anymore because the CNC machining works to remove the metal material faster and easier long with a high level of accuracy. The users can use anytime they want to produce parts or prototypes.

If you want to learn more about CNC machining, check Fictiv.

The Importance of Tolerances for Precision Machining

Tolerance has an important role in the precision machining . The purpose is to get the amount of deviation in a specific dimension of a part. You have to consult with the project manager to make sure that the process achieves a part as precise as it can.

Common Materials

CNC machining is more flexible than a traditional process. Due to its flexibility,it is able to produce a variety of materials including aluminum, stainless steel, copper, steel, brass, titanium, sterling silver, bronze, and many more. The process is also useful for industries involving hard plastic, nylon, acetal, polycarbonate, polystyrene, acrylic, fiberglass, carbon fiber, PTFE, ABS, and PVC. The process determines the surface of the final product. A high-quality CNC milling process produces a smooth and matte appearance surface which makes the final part or product looks great.

So, if you need help to create some parts or prototypes involves machining processing, you can use the CNC machining serices. Nowadays, you can find the service easier because artmachining.com has the machining parts China service. The service covers custom CNC parts, CNC metal parts, machined aluminum, prototype production. The most important thing, the process can be done faster and easier to produce a high-quality final product and the end users will love it.