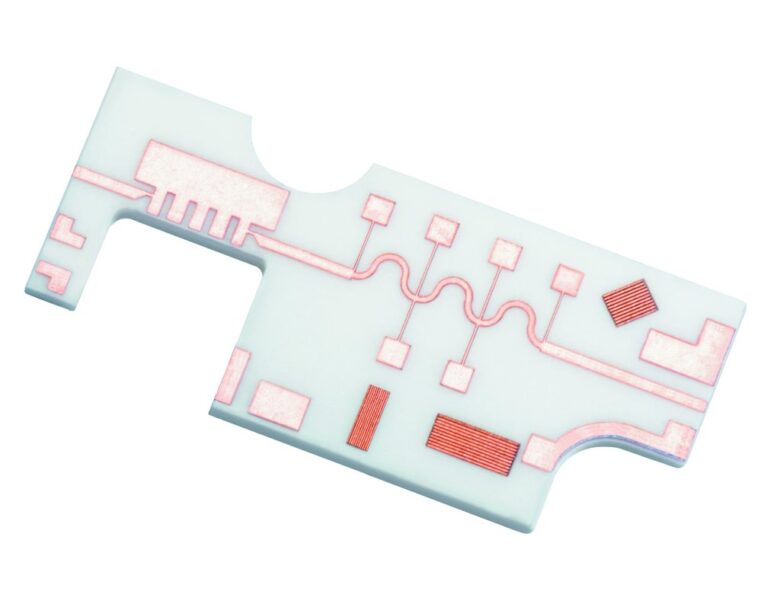

Every piece of technology has one vital part that it cannot operate without. This is a printed circuit board or PCB. While PCBs are normally made out of copper foil and some substrate such as glass fiber or other material, we can also make them out of ceramic.

Ceramic PCBs are the latest “hit” in the industry. They go through a similar making process but their application is mostly with high-powered and mostly electrical gadgets or machinery.

The fact that they’re ceramic means these PCBs come with their own set of pros and cons. And if you’re looking to find out more about that, then this is the article for you. So with all that said, let’s start.

What Are Ceramic PCBs?

Due to the high durability of the material under specific conditions, the aerospace and military industries are the two most common industries that employ modules and gadgets with circuit boards made from this material. The heat dissipation is a huge reason what makes them so highly sought-after in these two industries.

While we will get to the other pros and cons later on, we must talk about what makes them so unique.

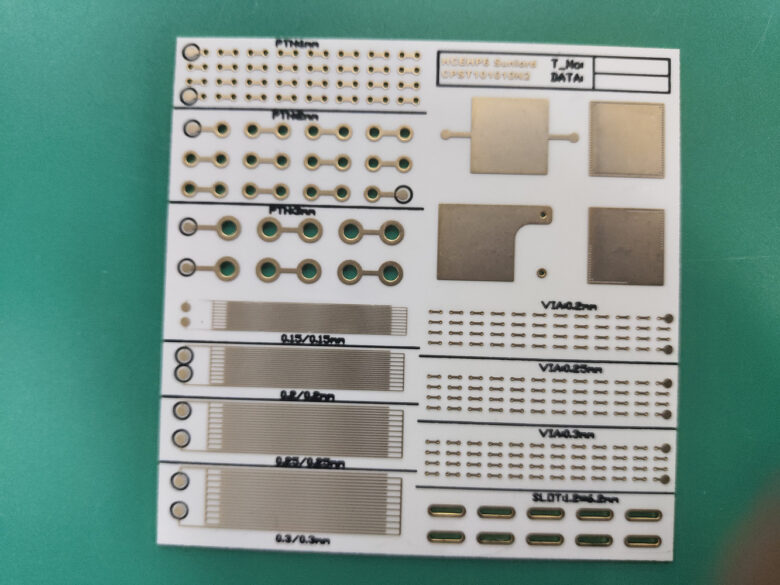

There are two most common substrate materials used in the making of these PCBs. The first we’ll talk about is alumina. When compared with other materials, alumina performs well. This is taking into account various properties, which we’ll get into greater lengths later on.

Another reason why alumina is a good substrate material is its high strength. But it isn’t only its strength that makes it so valuable. The material is exceptionally good with chemicals. This is due to its unprecedented chemical stability. Availability is yet another factor why ceramic substrates are made from this material. With all that said, we will not discuss another option. Alumina might be a good choice, but there is yet another kind of material that bolsters greater properties. That one is Aluminum Nitrite.

When compared both, aluminum nitrate is better as an insulator. This means that you can put it under higher voltage and it will perform better. Experts say that the thermal conductivity of aluminum nitrite is nearly 10 times better than that of alumina. This makes it better when used with high-powered electrical machinery that can reach voltage usages of over 170 w. Due to its superior comprehensive properties, aluminum nitrate is frequently used with power modules, microelectronics, power electronics, hybrid microelectronics, and more.

What this all tells us is that ceramic PCBs are excellent due to the specific properties of the substrate material. Aluminum nitrate substrate has clear and obvious advantages when compared with other substrates. If you’re thinking of ordering ceramic PCBs made from aluminum nitrate, then make sure to visit www.pcbonline.com.

Now that we’ve explained what these PCBs are and what are they made of, let’s dive into the pros and cons.

Pros and Cons of Ceramic PCBs

Let’s start with the pros.

Pros:

1. Cost-Effectiveness

A clear advantage of ceramic printed circuit boards is its cost-effectiveness. Ceramic isn’t an expensive material but neither is the substrate used, in our case aluminum nitrate or alumina. This means that manufacturers making PCBs do it at a very low cost. But not only that, the machines, devices, and gadgets that use these circuit boards also perform at a more cost-effective rate than normal circuit boards.

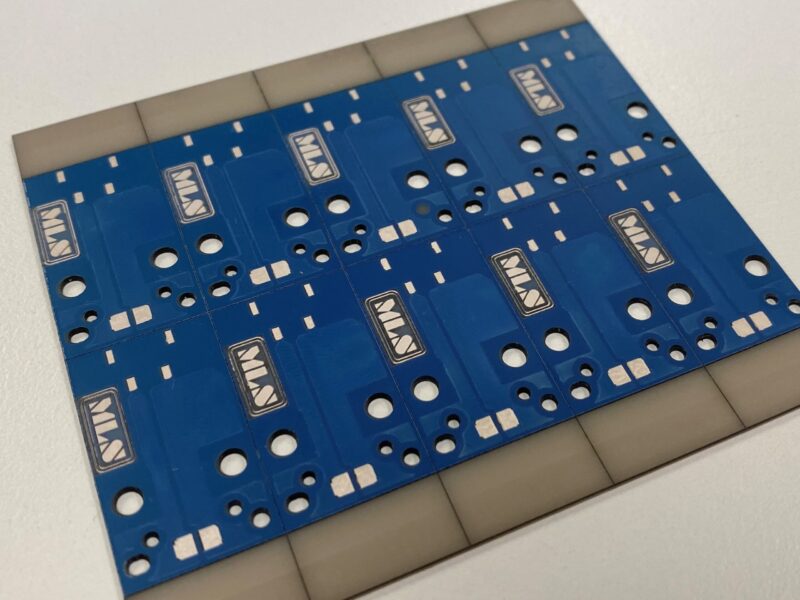

2. Easy Multi-Layering

The ability to use more than one layer in the making of the circuit board is also a huge advantage. Ceramic has excellent strength so circuit boards made from it can be made in multiple layers. The strength of the material means you can add another layer on top of it, without compromising the components.

This gives you a clear and obvious advantage. A multi-layered PCB means it can perform much more complex tasks and work. Naturally, this gives us more complex PCBs that also make the devices much better. It is precisely because of the multi-layering as to why PCBs made from this material have greater application in more complex industries.

3. High-Quality Insulation

Normal circuit boards are no stranger to voltage issues. This cannot be said with ceramic printed circuit boards as they bolster greater insulating properties. Since they are made from materials that are considered excellent insulation materials, it makes the PCBs good at that as well. This makes them very effective when needing to insulate electrical resistance in devices, gadgets, and machinery that are prone to outages.

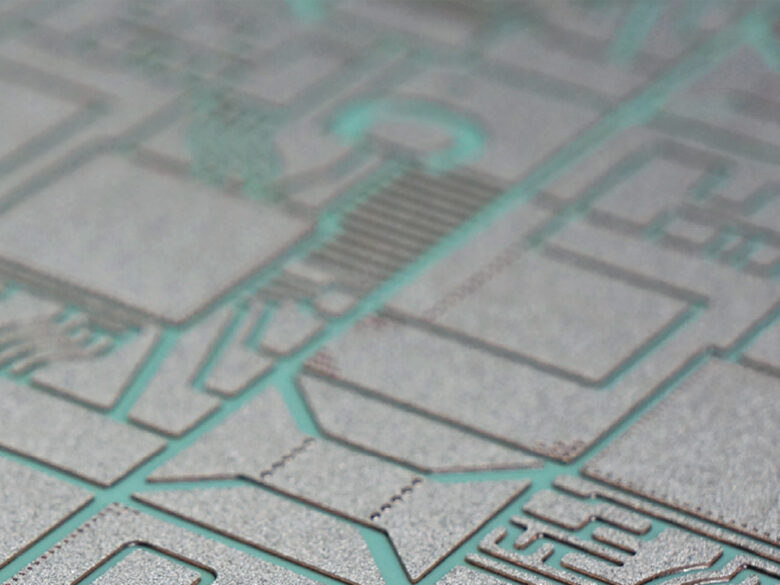

4. High Thermal Conductivity

When it comes to a gadget’s or device’s ability to transfer heat energy, none do it better than those with ceramic circuit boards. Since ceramic has excellent thermal conductivity, the circuit board will perform better in situations where the device is in contact with excessive heat. The ceramic will protect the device from getting damaged and even control the temperature. When the device has a multi-layered ceramic PCB, it will give it even more protection from heat.

Cons:

Now let’s talk about the cons.

1. Cost

We mentioned earlier that ceramic isn’t an expensive material. With all that said, it is more expensive than other materials used when making normal circuit boards. This means that not every industry needs ceramic circuit boards and only those that require the before-mentioned advantages. As we’ve mentioned plenty of times in this article, the biggest industries that use these circuit boards are the military and aerospace.

2. Prone to Damage

Handling is yet another reason why many industries stay away from them. While they are durable from heat and electrical damages, they are still fragile and will require a lot more time to repair if damaged, compared to normal circuit boards. Due to their size, they’re meant to fit into tight spaces of the machinery that uses them must be made much bigger.

Conclusion

The pros greatly outnumber the cons and that is a huge reason why you should always go with circuit boards made from ceramic. The fact that these types perform much better than normal circuit boards ensures that you’re making a better product overall.