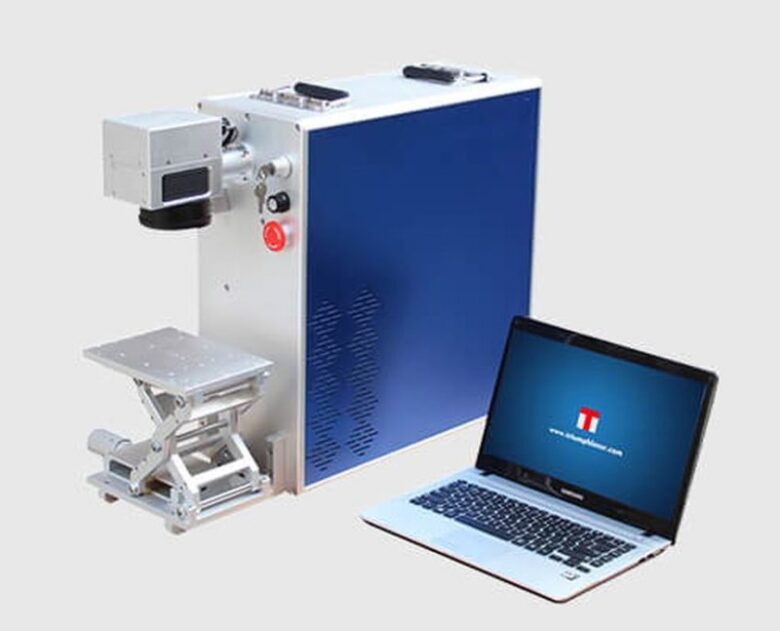

The innovations that are implemented for commercial and industrial purposes grow each day with advanced technology leading the way. The Fiber Laser Marking Machine is a typical example of technology at work in production today.

Combining the laser marking technologies available on the market with requested materials to work on, Fiber Laser has revolutionized the modern approach it has today. The other more familiar name for fiber laser is metal laser engravers, usually associated with the engraving procedure with various materials. The well-known fact is that fiber laser is part of the solid-state lasers family, and is a new popular laser marking technology ultrafastsystems.com which allows labeling an infinite number of materials requested from customers in all parts of the globe.

Understanding how fiber laser marking machine works is essential if you are considering purchasing them to boost your business. The target was to be able to sue a low maintenance solid-state laser source in order to engrave as many different materials as you can think of. This rigorous task was achieved through the use of advanced fiber pumping technology, which is necessary for attaining their conductivity. The fiber laser marking systems is depended on the pumping technology or simply said, pumping the fiber rays to the optical heads with the assistance of diodes emit lights.

The marking on the chosen surface of the material is done when the laser beam expands from the optical head shaping the mentioned surface of the material into the reality we intended to see. With the said above procedure, laser marking is capable of accomplishing through bonding the necessary materials, by laser engraving, through etching area with a color change of the material, removing the top layer, and with MOPA laser marking.

The commercial and industrial use is highly thankful for laser engraving machine for metal parts(gold, stainless steel, silver, bronze, platinum, brass), different types of plastic(PVC, ABS, PE, PP), aluminum, tungsten, medical-grade alloys, carbide, etc. The one solution that any manufacturer interested in the topic at hand must have is the fiber laser marking machine because of the options it brings to the table. We suggest visiting Heatsign for more information on this topic.

The benefits of the fiber laser marking machine are indeed countless. The fact that the working and expected lifespan of the fiber laser is over 100000 hours, and no need for maintenance because air cooling is used are the selling points everyone gets attached too. Note that there are no dangerous chemicals used for marking, environmentally friendly, reliable, and safe to work with above all.

Depending on the chosen model, working area, laser output power, marking line speed, and depth. As mentioned above, criterium goes up, so those the price follows accordingly. Additional options available will increase the total cost from 20% to almost 50%. We suggest specifying your requirements before making your mind up, on which one is more or less suitable for the task in front of you.

The help of the Fiber Laser Marking Machine is firstly practical, economical in the long period, and an investment required in the time when technology evolution will wait for no one.