One needs an electrical top-up before the supplier imports electrical products or equipment from overseas manufacturers to provide a certified testing report relevant to the department of the government to avoid any probability of the risks. If an imported product has been tested beforehand, the product still needs to pass a minimum level called the Top-Up test, which has different criteria overseas and in India. The staff is very familiar with the requirements and can guide the customer all the way through to achieve regulatory operations in Australia, New Zealand, and many other places.

The NZRCM also consists of the facility to test the motors up to 20Kw with capable torque of 0-100 NM. This dynamometer testing system includes high-precision, a power monitoring capability, along with torque and speed control.

A number of load tests can be performed on such devices as electric motors, induction motors, wind turbines, pumps, fans, and a self-balancing vehicle.

ACTNZ also offers options of full or partial testing for different types of cables like the TPS cables, flexible cord test, a fiber cable test, and a cyber-cable test.

When buying a product online, the customer expects a full disclosure about the product, which includes the details of making it sometimes and it’s testing procedure. At the request of clients, they can provide a full product test, top-up testing, or specified testing on certain household products, industrial equipment, lamps, information technology equipment, garden tools, and farm pieces of equipment. Collaborating with the lab partners and working along with them means offering services to almost any product standards for EMC, Radio, and Radiation exposure for different varieties.

Vibration Test

The vibration test is widely used in defense, aviation, aerospace, communications, electronics, automobiles as well as home appliances. It helps in discovering the faults at an early stage by stimulating the working condition, predicting the model failure, and the dynamic behavior of the product, which in turn improves the reliability and in-use performance.

UV radiation test

The Ultraviolet exposure that is UV radiation test is specially designed to figure out how a product will impact the effects of ultraviolet radiation or the test can or cannot create an effect on the products. Exposure to these radiations creates certain effects on the products like material fatigue and reduction of strength. These radiation tests test the components or products, which allows the engineers to reproduce the favorable conditions for the product. These tests also promote the level of resistance that the product offers along with its packaging. In the winter season, importing heating products has a large demand in New Zealand. When one imports any sort of electrical appliances or products, they need an assurance that these products are approved as the heating appliances are at high risk. The company has experience in-room heating tests, outdoor radiant tests, heat pump tests, dehumidifier tests, and underfloor heating tests. Thus electrical testing is a very common phenomenon before buying or selling any products, and a large variety of testing has come up nowadays as offered by NZRCM.

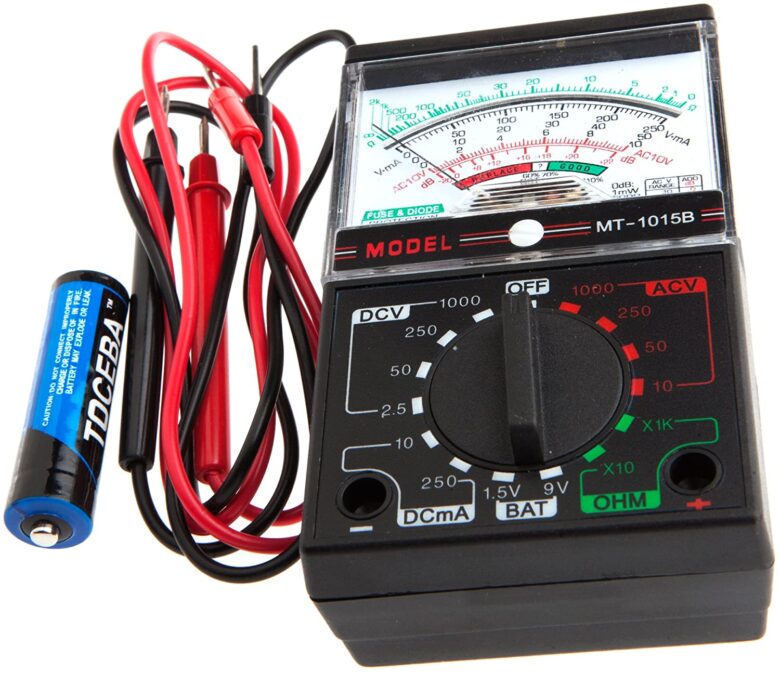

What are the Different Types of Instruments used in Electrical Lab Testing?

When it comes to electrical lab testing, there are arrays of different types of instruments that are used. Below, you will find a brief overview of a few of them.

- High Voltage Tester or HIPOT

- Insulation Resistance Meters

- Impulse Winding Testers

- Battery Tester

- DC Resistance Meter

- Automatic Transformer Tester

- Winding Component EST tester

- Power Analyzer

- Power Meter

- Frequency Response Analyzer

- Impedance Analyzer

- Laboratory Power Amplifier

- Selective Level Meters

- Ground Bond Tester

- EN60950/IEC Impulse Tester

These are some of the many different types of instruments that are used for electric lab testing. All these instruments have specific usage, and together, they form the basis of a successful lab testing environment.

Some of the Basic Equipment which is used

There are a few basic types of equipment, which are essential for all kinds of testing. Here is a brief insight.

- Voltmeter: This device is used for measuring voltage, which is one of the basic steps in all kinds of electric lab testings

- Ohmmeter: Measuring resistance is another important aspect of lab testing; ohmmeter is used for this purpose.

- Ammeter: Ammeter is used for measuring current

- LCR Meter: It is used to measure the LCR values. Here LCR stands for Inductance, Capacitance, and Resistance, respectively.

The following devices are used to test the stimulus of a circuit which is under test

- Signal generator: It is a type of device which generates different types of electronic signals with certain properties like frequency, wave shape, and amplitude.

- Power Supplies: It is a type of electric device which is designed to feed an electric load with electric power. The main function of a power supply is the conversion of the electric current generated from a particular source to the correct current, voltage, and frequency in order to offer power to the load.

- Pulse Generator: It is a type of equipment or an electronic circuit that is used for the purpose of generating rectangular pulses. Pulse generators are primarily used for analog circuits and also digital circuits.

- Digital Pattern Generator: It is used for generating digital electronics stimuli. A digital pattern generator is a specially designed software or test equipment. One of the main functions of a digital pattern generator is to stimulate the inputs of a digital device.

When it comes to Electrical Lab Testing, it is a very complicated process, which requires a great deal of technical expertise and different types of equipment. It is essential to have a clear and thorough knowledge about this equipment and its functionalities.

It needs to be mentioned in this regard that when it comes to most of the electronic and electrical equipment, it is mandatory to run a lab test. Through a proper lab test, various aspects like safety, longevity, loopholes, and other areas can be figured out. A lab test failure should ideally lead to the rejection of the object in question.