Engineers and designers have avoided stainless steel for a long period of time perhaps because of its high costs. However, the advantages of stainless steel will totally befit the initial investment. The material has awesome value in a fabrication project.

Let’s quickly glance over what stainless steel really is. As per the British Stainless Steel Association, this is an alloy of iron. It contains at least 10.5% chromium. The latter material produces a thin coating of oxide on the steel surface. This is referred to as the passive layer. The chromium available in the steel makes it corrosion-resistant, durable and excellent.

Types of stainless steel

Stainless steel is divided into five types:

Austenitic – This is one of the most common variations of steel. This type of steel can be easily weld and given shape. The strength mainly comes from added nitrogen, manganese, and nickel.

Ferritic – This chromium-based steel contains a low proportion of carbon. It can be used in where welding is not required. This is the best for marine application design as it can resist seawater corrosion. Also, it is magnetic in nature.

Martensitic – Applications which do not demand high strength and moderate corrosion resistance use this type of steel. It has moderate corrosion resistance. It is used in producing dental and surgical equipment, cutting tools, knives, etc.

Duplex –Such steel has high strength and is also resistant to corrosion. This is formable and is considered an amazing element in welding.

Precipitation hardening – Such steel can be shaped into making intricate and durable design. Aluminium, niobium, and copper give it the strength.

Now, let’s come to the benefits of stainless steel in any fabrication project. Nowadays, modern designers and engineers use this metal due to its efficiency and efficacy.

Advantages of stainless steel

Before starting with stainless steel, let’s mention that stainless steel is not free from cons. Just like any other metals, it has its share of disadvantages. Some of its disadvantages include a high initial price, the metal has to be handled with brilliant quality equipment, etc. Nevertheless, the benefits of this metal far outweigh the cons of the metal. There are unique advantages of stainless steel for your fabrication projects.

Some of the advantages of the metal include, but not limited to the following:

Easy to Work

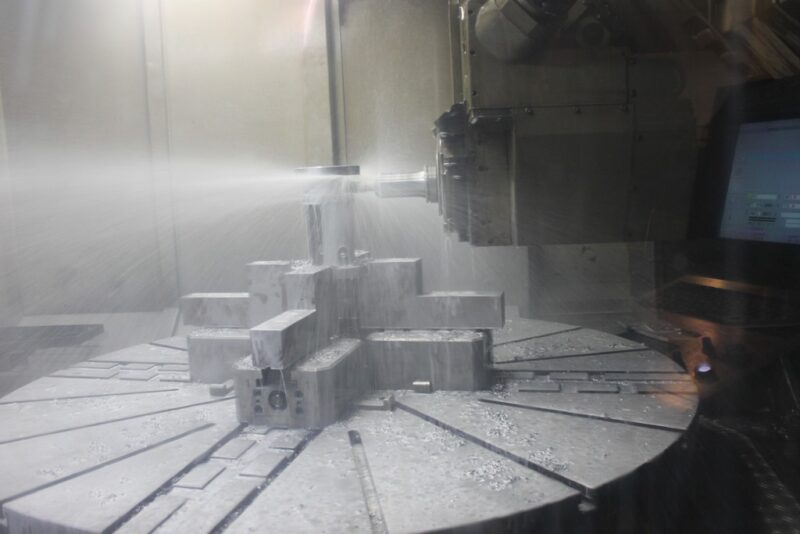

Stainless steel is an ideal option for a fabrication project if the selected fabricator hates outdated machinery. However, make sure that the engineers use top-notch, modern pieces of equipment. Steel is easy to cut, shape and welded into designing a brilliant end product. According to metalworkmasters, modern machines offer advanced settings for performing even the most difficult welds. So, welds on steel won’t be much of a problem even for beginners.

Corrosion Resistance

One of the primary USPs of the metal is its unique ability to fight corrosion and heat. Are you interested in producing high-quality and rust-free products? If yes, then this can be the perfect choice for you. It can resist corrosion and positively impacts the value of any long term investment.

Chromium – an important element in stainless steel allows it to be rust-resistant. Further, as an alloy, stainless steel contains other elements like aluminium. Each of them resists corrosion in different ways. While using in wet applications, lower graded alloy work ideally. However, while using alkaline and acid solutions, a higher grade of alloy is the best option.

Long-term work

Working with stainless steel also has long-term value and we must not overlook that. From this perspective, it outweighs the bulk investment that you have to spend initially. Before diving into a fabrication project, you must keep an eye on the metal’s lifecycle. Selecting a low-maintenance product like stainless steel enables the engineers to focus more on the process and end-result.

Temperature proof

Stainless steel has a reputation for its ability to withstand a high amount of heat. Thus, this feature makes it suitable for developing applications that sustain high temperatures like feedwater heater, valves, boilers, and other types of heat exchangers.

Sustainability

Stainless steel has recyclable nature. Most of the modern companies are concerned with the impact of manufacturing on the surrounding ecosystem and environment. Investing in this metal is a great idea. That way you can be certain that your products or even the manufacturing process will mitigate some of the adverse impacts. The credit goes to the sustainable and recyclable nature of stainless steel.

Products demanding high strength to weight ratio

Often some applications or products require a high level of strength to weight ratio. Stainless steel is better than other materials as it can tolerate chemical and heat damage. Industrial equipment and skyscrapers use stainless steel like the options offered here (https://fastmetals.com/pages/plate-stock) due to its durability and strength.

Aesthetics

Fabrication is not only about engineering. This is a craft with a seamless blend of creativity, technology, and engineering. The end product, no matter how durable or strong it is, will not be appealing to the customers if it is not visually appealing. Restaurant applications or any other appliances that require beautiful and hardy exterior use stainless steel. Further, this allows them to maintain the beauty of the surface regardless of heavy usage. Architects also prefer to use stainless steel for creating the exterior of their buildings. That way, the metal looks to be new even after years of long exposure to wind and rain.

Conclusion

Working with stainless steel can be a challenge only if your fabricator uses outdated equipment. However, by using modern and cutting-edge tools, they can easily cut, shape, and weld stainless steel without breaking a sweat.

Companies too prefer to use this for their fabrication projects. Thanks to all the benefits mentioned above. Also, that the products will feature hardy and stunning exteriors. Furthermore, standing against heat, corrosion, and rough usage is yet another crucial consideration for many. Lastly, the manufacturing process and the used metal is environmentally friendly. And so, the governments, too, sanction the increasing usage of stainless steel.