Flame treating, a technique as intriguing as its name suggests, has carved a niche for itself across a spectrum of industries. At its core, flame treating is a surface modification process, harnessing the power of heat to transform material surfaces for specific applications.

Its versatility is evident in its widespread use, from the automotive sector to the intricate world of medical devices. This post delves deep into the wonders of flame treating, shedding light on its principles, benefits, and diverse applications.

Understanding Flame Treating

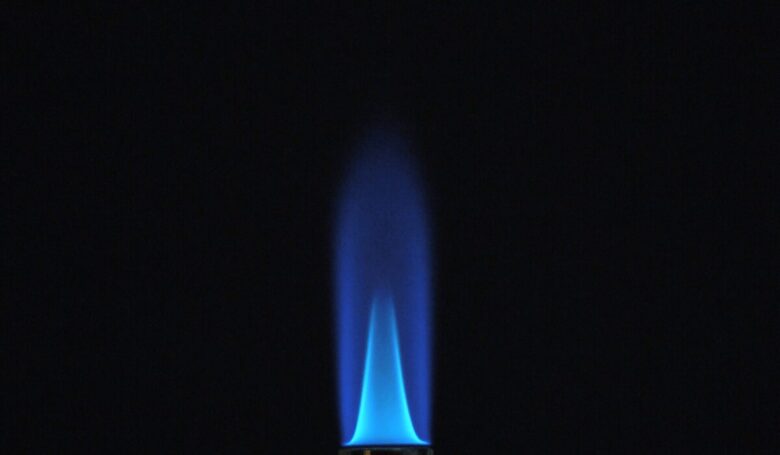

Flame treating is a fascinating dance of heat and material. By exposing a material’s surface to a flame, its properties are altered, often to enhance adhesion or modify surface characteristics.

The magic lies in heat activation. When materials, especially polymers, are subjected to controlled flames, their surface molecules reorient, increasing their readiness to bond with coatings or adhesives. This molecular ballet not only ensures better adhesion but also paves the way for improved product performance.

Benefits of Flame Treating

In the vast realm of surface treatment methods, flame treatment stands out, and for good reasons. Its primary advantage is the enhanced adhesion it offers, ensuring coatings, paints, or glues firmly grip the treated surface.

This process is especially vital for industries requiring robust bonding solutions. Flame treating can modify surface properties, tailoring them for specific applications, such as making plastics more receptive to inks.

And the cherry on top? It’s cost-effective, often reducing the need for expensive primers or additional treatments, saving industries both time and money.

Automotive Industry

The automotive world, with its relentless pursuit of perfection, has embraced flame treating with open arms. One of its standout applications is in enhancing paint adhesion on plastic components. This is crucial for parts like bumpers, dashboard elements, and other interior components.

Flame treating ensures that paints adhere flawlessly, resisting peeling or chipping, and contributing to the vehicle’s aesthetic and durability. This results in cars that not only look impeccable but also have a longer lifespan, reducing the need for frequent touch-ups.

Bakery and Cooking

In the culinary world of baking and cooking, flame treating introduces a touch of artistry and precision. Chefs and bakers utilize flame-treating techniques to caramelize sugars, create a perfect crust on crème brûlées, or give a smoky char to vegetables and meats.

This controlled application of flame ensures that dishes not only taste exquisite but also have a visual appeal that’s second to none. For dishes that require a delicate balance between texture and flavor, flame treating is the secret weapon and this is where Flynn Burner Corporation can help.

It elevates the sensory experience, making every bite a harmonious blend of taste and texture, delighting food enthusiasts around the world.

Packaging and Printing

In the vibrant realm of packaging and printing, presentation is paramount. Flame treatment plays a pivotal role here, especially when dealing with plastic packaging materials. By enhancing ink adhesion, ensures that prints are vivid, durable, and resistant to smudging, elevating the overall product appeal.

This is especially crucial for products that face rigorous handling in stores or during shipping, ensuring that the packaging remains pristine and attractive to potential buyers.

Electronics and Semiconductors

In the intricate world of electronics and semiconductors, precision is paramount. Flame treating, with its meticulous approach, aids in bonding and sealing electronic components, ensuring they function optimally. This is vital for devices like smartphones, laptops, and other gadgets that consumers rely on daily.

From ensuring a chip adheres perfectly to its substrate to sealing components, flame treating is an unsung hero in electronics manufacturing. It plays a pivotal role in ensuring longevity and reliability in the gadgets we use daily, reducing the need for frequent replacements and repairs.

Medical Devices

The medical device industry, with its stringent standards, leverages flame treating for two primary purposes: sterilization and surface modification. Sterilizing instruments is crucial to ensure patient safety, eliminating any potential contaminants.

On the other hand, surface modifications, achieved through flame treatment, enhance biocompatibility. This ensures that devices, whether they’re implants or surgical tools, interact harmoniously with the human body, reducing the risk of adverse reactions or complications during medical procedures.

Textile and Apparel

The textile and apparel industry, always in vogue, employs flame treating to stay ahead of fashion trends. By improving dye penetration and print quality on fabrics, flame treating ensures that colors are vibrant, patterns are crisp, and the end product is nothing short of stunning.

This meticulous process results in garments that not only look good but also last longer. They resist fading even after multiple washes, offering consumers better value for their money. This means consumers can enjoy their favorite outfits for extended periods, enhancing sustainable fashion.

Aerospace and Defense

In the high-stakes aerospace and defense sectors, precision and reliability are non-negotiable. Flame treating contributes significantly here, especially in bonding composite materials and applying flame-retardant coatings.

These applications not only enhance product performance but also play a pivotal role in ensuring safety. Whether it’s an aircraft’s exterior, its internal components, or protective gear for soldiers, flame treating ensures durability.

It provides an added layer of protection against potential hazards, ensuring that equipment can withstand extreme conditions and challenges.

Furniture and Woodworking

Wood, with its natural charm, sometimes needs enhancement, especially when it comes to accepting paints or stains. Flame treating ensures that wood surfaces are primed to absorb paints evenly and stains deeply, resulting in finished products that are both durable and aesthetically pleasing. This means furniture pieces that not only look good but also resist wear and tear, offering longevity.

Plastic Manufacturing

Plastics, ubiquitous and versatile, often need a specialized touch to reach their full potential. Flame treating steps in here, increasing surface energy and ensuring effective adhesion, whether it’s a coating, a print, or another layer of plastic.

This intricate process ensures that products, from everyday containers to children’s toys, have a finish that’s both attractive and durable. It meets and often exceeds consumer expectations, ensuring that plastic items remain functional and aesthetically pleasing for longer durations.

Environmental Considerations and Safety

While flame treating offers a plethora of benefits, it’s essential to address its environmental footprint. Ensuring that the process is energy-efficient and minimizing emissions are crucial for a sustainable future. Additionally, safety cannot be compromised.

Adopting protective measures, training personnel, and ensuring proper ventilation are essential to harness the benefits of flame treating responsibly, ensuring both worker safety and environmental protection.

Conclusion

Flame treating, with its myriad applications, is truly a marvel. Its ability to transform surfaces, enhance product performance, and ensure durability is unparalleled.

As industries evolve and product demands shift, understanding and harnessing the potential of flame treating will remain pivotal. Whether it’s a car, a medical implant, or a chic dress, the touch of flame treating ensures it’s the best version of itself.