The durability of materials is not just a technical concern; it’s a matter of safety, quality, and cost-efficiency. When materials fail, they can cause accidents, need replacing, and lead to extra costs. Because of this, understanding how long a material will last in different conditions is paramount. This is where climate tests come into play. By simulating different environmental conditions, climate tests give us a snapshot of how materials will perform over time, ensuring they’re up to the task for long-term use.

The Basics of Material Durability

When we talk about material durability, we’re referring to the ability of materials like metals, plastics, or composites to resist wear and tear during their lifetime. This quality is vital in a wide range of applications, from the construction of buildings and bridges to the manufacture of vehicles and household goods. For instance, engineers and manufacturers must consider the durability of steel when designing a bridge or the durability of plastic when creating a water bottle. This ensures that the final product is not just functional but also long-lasting, safe, and cost-effective.

The Impact of Climate on Materials

Climate significantly affects the durability of materials. For instance, a car part that resists wear in a temperate climate might corrode quickly in a salty, humid environment. Similarly, construction materials that hold up well in dry conditions may degrade faster in high humidity. Problems like these—corrosion, degradation, and even material fatigue—can severely shorten a material’s lifespan, leading to increased costs and potential safety risks. So, understanding how different climates impact various materials is crucial for ensuring their longevity and performance.

What Are Climate Tests?

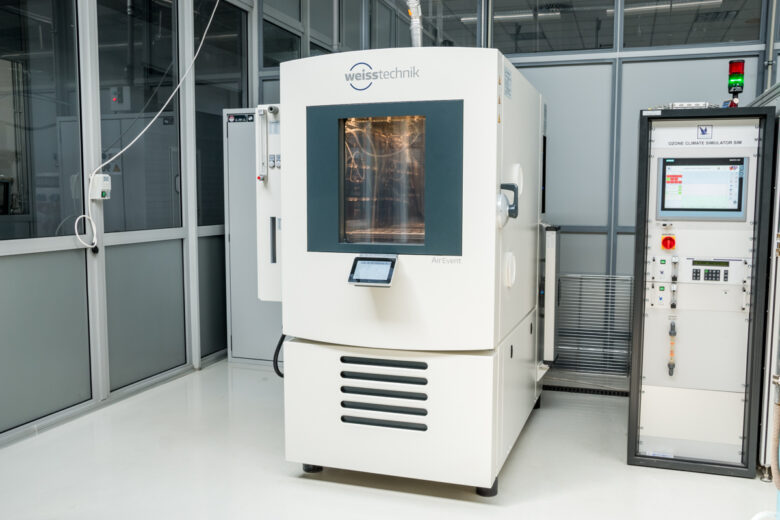

Climate tests conducted in an aging test chamber aim to solve the issue of material degradation caused by environmental conditions. These tests simulate a range of environmental stresses in controlled settings to predict how materials will perform in real life. Testing chambers can mimic conditions such as high or low temperatures, humidity, salt spray, and UV exposure. This helps scientists, engineers, and manufacturers make informed decisions about material selection and design, ultimately contributing to a product’s reliability and lifespan.

Types of Climate Tests

Several kinds of climate tests exist to evaluate material durability. Temperature tests expose materials to extreme heat or cold to see how they respond. Humidity tests focus on how materials react to moisture in the air. UV exposure tests determine how sunlight affects materials, particularly plastics and fabrics. Each of these tests plays a specific role. For example, temperature tests are vital for car parts that must withstand a range of climates, while UV tests are crucial for outdoor furniture. By using these tests in combination, experts can get a comprehensive understanding of a material’s durability.

Benefits of Conducting Climate Tests

Conducting climate tests offers several advantages. First, they help predict a material’s lifespan, allowing for better planning and reduced maintenance costs. Second, they improve safety by identifying potential points of failure in materials before they’re used in real-world applications. Lastly, knowing a material’s limits can lead to innovative designs that incorporate more durable, long-lasting components, giving a competitive edge to companies in the market.

Industries That Rely on Climate Testing

Climate testing is a must in sectors like automotive manufacturing, aerospace, and construction. Cars need to function well in different climates, airplanes must withstand extreme conditions at high altitudes, and buildings require materials that can endure various environmental stresses. In all these industries, failing to use durable materials could result in catastrophic failures, hefty repair bills, and even loss of life.

The Process of Climate Testing

Conducting a climate test involves multiple steps. First, experts decide which types of environmental conditions to simulate based on where the material will be used. Next, they place the material samples in specialized chambers that can mimic these conditions. During the test, they monitor how the material reacts, often using sensors and visual inspections. It’s crucial for these tests to be accurate and repeatable, ensuring that the results are reliable and can be used to make sound decisions.

Real-Life Examples

Real-world case studies further underscore the value of climate testing. For instance, in the automotive industry, climate tests have helped manufacturers improve the lifespan of car batteries, leading to fewer replacements and higher customer satisfaction. In construction, advanced materials developed through rigorous climate testing have made buildings more energy-efficient and resilient to natural disasters. These successes not only highlight the reliability of climate-tested materials but also represent significant advancements in their respective fields.

Challenges in Material Durability

Even with advanced testing, challenges still remain in ensuring material durability. Extreme conditions, such as drastic temperature fluctuations or high-pressure environments, can push materials to their limits. In addition, chemical exposures, like salt in ocean environments, can lead to rapid degradation. Wear and tear from regular use also impacts longevity, especially in materials subjected to constant mechanical stresses, like gears in machinery. Climate tests help us address these challenges by providing vital data. This data can then be used to tweak or improve material composition, leading to products that are not just more robust but also more durable for the long haul.

Sustainability and Longevity

Durability doesn’t just benefit us in the short term; it has long-term environmental impacts too. Longer-lasting materials mean fewer replacements, leading to reduced demand for raw materials and less waste generated. It also means fewer transportation-related emissions because of the reduced need for shipping new products. More durable materials often require less maintenance, translating into saved energy and resources over the material’s lifetime. This isn’t just a financial benefit—it also reduces the material’s overall carbon footprint. In this way, focusing on material durability through climate tests isn’t just good engineering or smart economics; it’s also a significant step toward more sustainable living.

Conclusion

Mastering material durability is essential for a range of applications, from everyday products to critical infrastructure. Climate tests provide an invaluable tool in this mastery, simulating the environmental stresses that materials will face in their lifetime. By understanding these impacts, we can create safer, more reliable, and more cost-effective products and structures. Given its role in enhancing material longevity and, by extension, sustainability, climate testing is something that we should all consider critical for the future.